Introduction

DPH Engineering is a Authorized Distributor Syntron Vibrating Feeders come with a basic control that lets you change the amount of material that flows through them by changing the amplitude of the feeder pan. An operating switch, a fuse, and an adjustable control to change the amplitude are all parts of standard control units. For an easy, thorough installation, just connect the control box to an electrical source and the electromagnetic vibrator or feeder. On request, controls can operate at voltages other than 115, 230, or 460 volts and 50 or 60 cycles of power. There are control units available for various feeder applications. Control system can be provided by Syntron Material Handling and tailored to your needs. The Power Pulse Dust Tight RC Control and the Conductor 15 are two controls offered for quick turn delivery.

Feeder controls and system design are critical components in any water distribution system. Proper design can help ensure that your distribution system operates efficiently and safely and also helps in the material and handling process. A feeder has to guarantee the position and the orientation of the components it supplies to the assembly system. As the feeder stops, material flow stops as well and when the feeder is turned on, there is a close correlation between the speed of its operation and the rate of discharge of the bulk material.

In order to properly design your feeder controls, you need to understand the various types of feeder systems and their associated requirements. For example, a gravity fed system typically requires less control than an electric fed system. Vibrating feeder is best fitted for dosing and conveying the majority of bulk materials. Vibratory feeders are able to convey a broad range of particle sizes and are also the most widely employed and versatile part-feeding devices for material handling conveyor systems.

Feeder controls can also help you optimize your system performance and work best in the material handling systems. For example, by adjusting the flow rate of water to a tap, you can adjust the temperature and pressure at the tap. This can help ensure that your water is delivered at the right temperature and pressure.

Syntron feeder controls and systems

Dph Engineering is an Authorized Distributor of Syntron Vibrating Feeders that are furnished with a standard control to vary the flow of material through the feeder by adjusting the amplitude of the feeder pan. Standard control units include an operating switch, fuse and adjustable control to vary the amplitude. Controls are available for 115, 230 or 460 volts, 50 or 60 cycle power and are available for operation at other voltages upon request. Control units for multiple feeder applications are available. For special electrical standards, custom control enclosures can be provided. In addition to the standard controls listed here, Dph Engineering Material Handling can provide control systems built to meet your requirements. Velocity RS drives can be provided with a separate, standard RC control (see pages 20-21) and are also available with a self-contained rectifier. Units with a self-contained rectifier operate at full stroke.

|

Control Model |

Volts |

Amps |

Enclosure |

Approvals |

Intermittent Contacts |

Intensity |

Soft Start | Voltage Regulation | RC

Output |

AC

Output |

| Power Pulse RC WT | 115/230 | 5 | Nema 4 | cUL | ● | Potentiometer | ● | |||

| Power Pulse AC WT | 115/230 | 5 | Nema 4 | ● | Potentiometer | ● | ||||

| Conductor DC 15 | 115 | 15 | Nema 4 | cUL | ● | POT / 4-20mA | ● | ● | ● | ● |

| Conductor DC 28 | 230 | 8 | Nema 4 | cUL | ● | POT / 4-20mA | ● | ● | ● | ● |

| Conductor DC 118 | 115 | 18 | Nema 12 | cUL | ● | POT / 4-20mA | ● | ● | ● | ● |

| Conductor DC 218 | 230 | 18 | Nema 12 | cUL | ● | POT / 4-20mA | ● | ● | ● | ● |

| Conductor 420 | 340/480 | 4-20 | Nema 4 | cUL | ● | POT / 4-20mA | ● | ● | ● | |

| Conductor 518 | 575 | 4-18 | Nema 4 | cUL | ● | POT / 4-20mA | ● | ● | ● | |

| Conductor CH 15 | 115 | 15 | Open Chassis | cUL | ● | POT / 4-20mA | ● | ● | ● | ● |

| Conductor CH 28 | 230 | 8 | Open Chassis | cUL | ● | POT / 4-20mA | ● | ● | ● | ● |

● Standard in the model listed

* Conductor controls are also available in open chassis models for ease in mounting in your system controls.

Note: Some open chassis models have reduced amperage capability. Contact Syntron Material Handling for details.

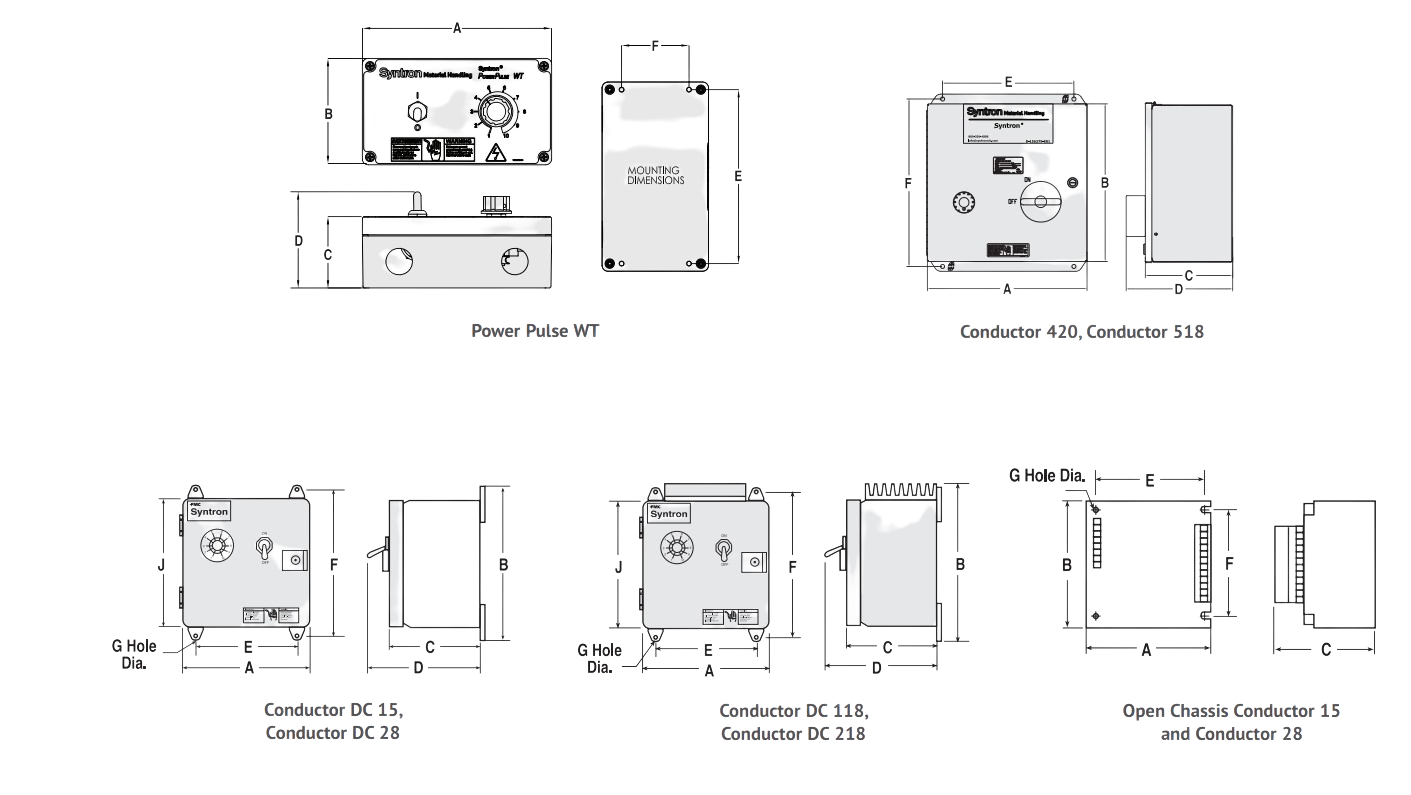

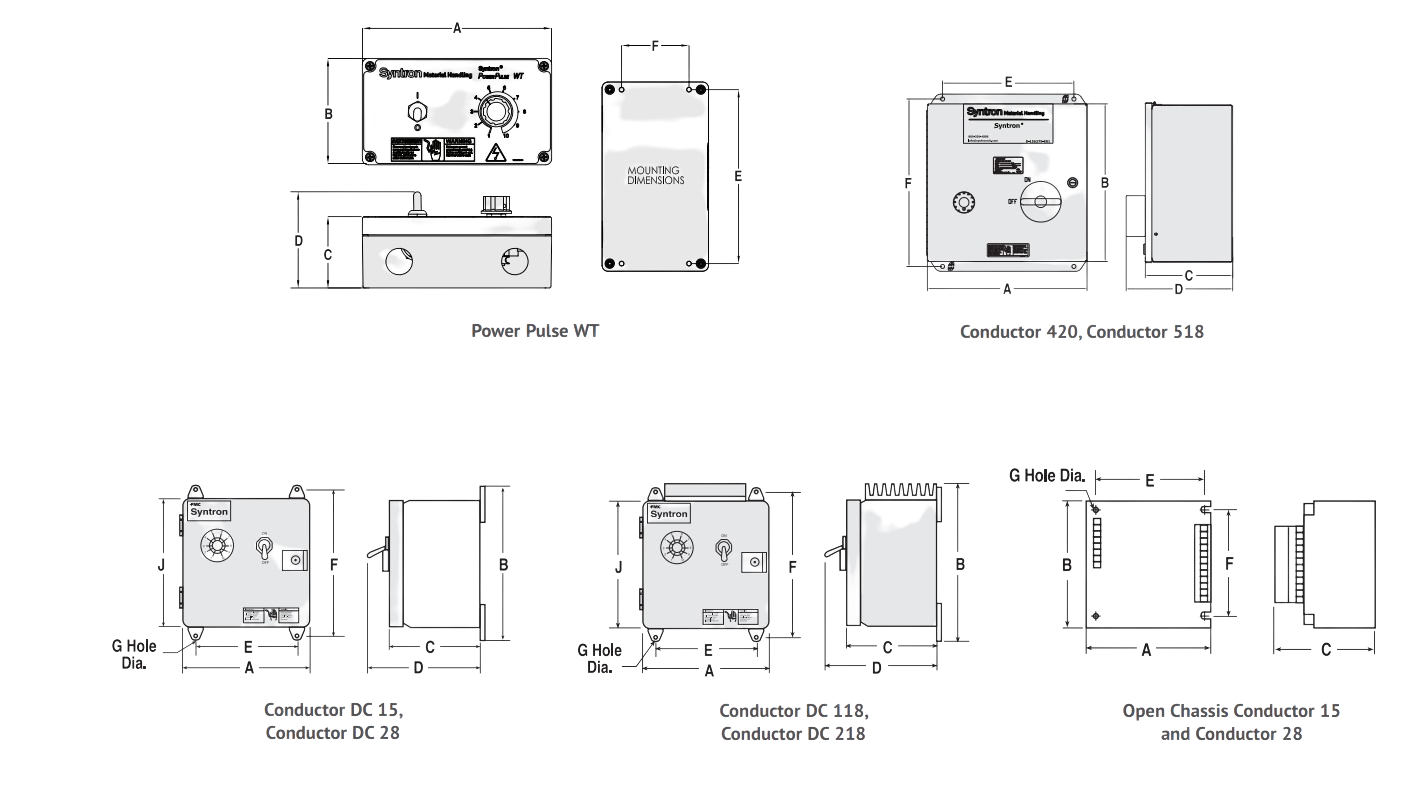

Control Dimensions

| Control | A | B | C | D | E | F | G | H | J | Weight | ||||||||||

| Model | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | lb | kg |

| Power Pulse WT | 6 1/4 | 160 | 3 1/2 | 89 | 2 1/4 | 57 | 3 1/4 | 82 | 5 3/4 | 146 | 2 1/4 | 57 | – | – | – | – | – | – | 1 1/4 | 5 |

| Conductor Series | ||||||||||||||||||||

| 15 & 28 Enc. | 8 | 203 | 9 1/2 | 242 | 4 3/4 | 121 | 5 5/8 | 143 | 6 1/4 | 159 | 8 5/8 | 219 | 5/16 | 8 | – | – | 8 | 203 | 7 | 3.18 |

| 118 & 218 Enc. | 8 | 203 | 10 | 254 | 4 3/4 | 121 | 5 5/8 | 143 | 6 1/4 | 159 | 8 5/8 | 219 | 5/16 | 8 | – | – | 8 | 203 | 8 | 3.63 |

| 420 & 518 Enc. | 12 1/4 | 310 | 12 1/4 | 310 | 6 | 152 | 7 13/16 | 198 | 10 | 254 | 12 3/4 | 324 | 0.3 | 7.92 | – | – | 12 | 303 | 18.5 | 8.4 |

| 15 & 28 Open Chassis | 3 15/16 | 100 | 3 13/16 | 96 | 3 1/16 | 78 | – | – | 3 1/4 | 82 | 3 1/4 | 82 | 0.18 | 4.5 | – | – | – | – | 0.58 | 0.26 |

Introducing the New PowerPulse WT

Type 4X Enclosure

- Corrosion resistant polycarbonate

- Water and dust tight design

- For indoor and outdoor use

- UL certified

- CUL certified

- Available in 115 and

230 volt 50/60 HZ

Practical Design

- Small lightweight control

-

Interchangeable with previous models

- Easy installation and operation

PowerPulse WT

| Feature | Benefit |

| Type 4X Enclosure | Protection against dust and water both indoor and outdoor |

| New Mounting Layout | Four hole layout allows for simple sturdy mounting |

| Interchangeable | Compatible with all old PowerPulse applications |

| Ergonomic Design | Easy to connect and install |

| 115 and 230 Volt Models 50/60 HZ | Suitable for domestic and international applications |

| Enhanced Circuit Board | Now UL and CUL Certified |

| New Board Dimensions | New board is interchangeable with previous PowerPulse RC enclosures |

Dimensional Data