Vibrating Conveyor

Syntron Vibrating Conveyor Manufacturer & Supplier In India.

Introduction

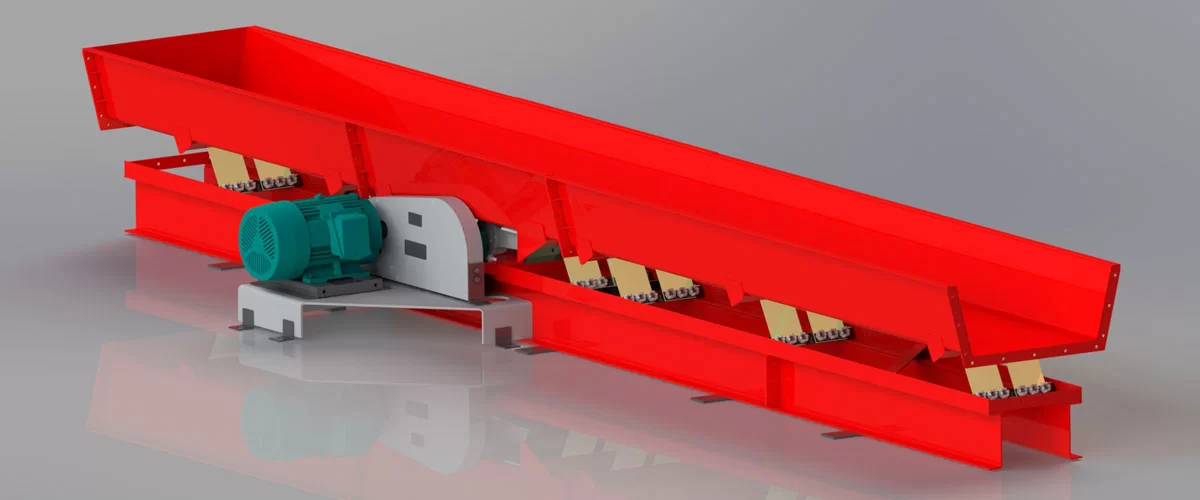

Vibrating Conveyor is used in transferring a wide variety of bulk materials along a trough with a uniform and consistent flow. A vibrating conveyor is robust conveying equipment used for fine to coarse-grained bulk materials. Whether this is powdery materials, gravel or coarse screen. They are very durable given that these materials are passed on a level plane. Most vibrating conveyor is basically directional – toss units which comprise of a spring-upheld flat container vibrated by a direct-associated unusual arm, pivoting capricious loads, an electromagnet, or a pneumatic or hydraulic cylinder

Flexmount Oscillating Conveyor

- Light to medium-duty applications

- Flat Springs

- Used in chemical, forest products, and metal processing industries

- Coilmount Oscillating Conveyor Large capacities of low to high-density materials

- Coiled Springs

- Free-Flowing, Sticky or Fragile Material Applications

- Modified for Screening, Scalping, Spreading and Dewatering Applications

Standard duty vibrating conveyors

For medium to light density material, such as plastics, wood, porous rock, and the like, standard duty vibrating conveyors are designed. Depending on requirements, this conveyor equipment can be both portable and modular, with capacities ranging from 1 to 40 tonnes per hour at up to 60 feet per minute. These conveyors are a dependable and secure solution for moving aggregate because they normally have a long lifespan and encounter little to no wear. They are used in manufacturing, polymers, processing chemicals and food, among many other things.

Tuned Two-Mass Model TM Vibratory Conveyor

These machines will transport massive amounts of information with straightforward, predictable efficiency. The Model TM conveyor is a two-mass, spring-coupled vibrating equipment that uses an eccentrically weighted shaft that is driven by a motor to produce the exciting force. The trough receives the exciting force from corrosion-resistant fiberglass springs, and the motion of the trough can be “fine-tuned” for certain purposes.

Features:

components installed separately for simple maintenance

fiberglass springs that are resistant to corrosion

a low profile with little headroom

simple controls using less power

Can be created for base or suspended mounting

Vibratory Feeders

The vibratory feeder is distinguished by its function, namely to uniformly feed materials into another device, even though it is not dissimilar from the operation of other types of vibrating conveyors. In continuous weighing applications where specific volume rates are required and alternative feeder types cannot be employed, these feeders are most helpful. Vibratory feeders or feeder conveyors are also employed in a bowl configuration to transmit irregularly shaped small parts, such as screws, rings, and more, in an orderly manner. They serve a variety of purposes in the manufacturing, food, hardware, and chemical industries.

For many international companies that are leaders and innovators in their fields, DPH Engineering is an authorized distributor for the Indian market. It serves as one of the remarkable conveyor manufacturers to its customers. We offer material handling equipment solutions to a variety of industries, including the food, power, paper, and cement sectors.

Vibratory Conveyors

Dph Engineering offers a complete line of traditional pitch-action style vibrating conveyors for light or extreme duty applications.

Vibratory conveyors use an angular pitch along with a controlled throw distance from the neutral rest position to propel product forward in the conveyor trough. The pitch of this action as well as the throw distance can be designed to suit a variety of applications.

Vibratory conveyors are used for stratifying products for screening applications, classification of products by size, fluidizing products for either drying or cooling applications, spreading products for uniform distribution transfer applications from different sized process outlets to downstream inlets, removing excess moisture from products, promoting leveling in product packing vessels, elevating products between process points or just general point to point conveying.

When it comes to conveying, the goal is clear: maximum speed with minimal product degradation.

Syntron conveyors from DPH Engineering can take you there. No matter the material — metal, glass, wood products, or chemicals — Syntron conveyors can provide an efficient and effective conveying solution system for your process. The technology behind DPH Engineering’s Syntron vibrating conveyors is based on a combination of natural frequency and positive drive action that results in low operating power requirements with minimum stress on drive components. The positive action eccentric drive ensures constant amplitude under most operating conditions. In addition, Syntron’s positive action drives provide uniform product flow as the process demands change. This feature eliminates the need for precise, continual drive speed adjustment. Syntron Vibrating conveyors from DPH Engineering are rugged, compact, and easy to install and maintain. Their natural, gentle conveying action makes these units ideal for handling a wide range of free-flowing bulk materials, including hot, abrasive, fine, dusty, lumpy, stringy, and other difficult-to-handle products. Because no single conveyor system is suitable for all applications, DPH Engineering manufactures two types of vibrating conveyors — the Flexmount conveyor and the Coil Mount conveyor. These two models cover most capacities and weight requirements for efficient, economical, industrial conveying applications. Base-mounted, non-isolated Flexmount, and Coil Mount conveyors must be mounted on a concrete foundation at grade level that is suitable to withstand the dynamic loads exerted. Please contact DPH Engineering to confirm actual recommended foundation requirements.

Features and Benefits include:

- Flexibility – Syntron vibrating conveyors are suitable for most applications operating conditions and arrangements —short or long runs, a wide variety of materials. Single or multiple discharge points provide a steady, even flow.

• Gentle Handling – allows the handling of thin, brittle castings with minimum degradation of fragile materials.

• Low Maintenance – only the drive requires lubrication. Low operating power requirements. Fewer moving parts result in less maintenance.

• Positive Drive – maintains conveying action even under operating surge load conditions.

• Designed to last – rugged construction to withstand demanding industrial environments and applications, even when sharp, abrasive materials are conveyed.

Flex mount Vibrating Conveyors

DPH Engineering’s Syntron Flexmount vibrating conveyors provide an economical means of conveying a wide variety of granular, free-flowing materials and odd-size materials such as metal scrap, with the assurance of years of dependable, trouble-free service.

Designed for light to medium capacity applications (up to 35 tph), these compact units are simple in construction, but are remarkably rugged and compact. Flex mount conveyors feature a positive action drive that provides the additional energy needed to handle varying loads beyond the natural frequency range of the conveyor. This enables the Flexmount conveyor to maintain a constant stroke whether loaded or empty. These conveyors are ideal for material handling applications in the chemical, forest products, metal cleaning, and food processing industries. Standard troughs for the Flexmount conveyor are 10 gauge mild steel construction with widths ranging from 8 to 48 inches. The troughs are also available in stainless steel. In addition, flanged troughs can be made of special materials. A variety of liner materials are available for handling corrosive or abrasive materials. Dust-tight or weather-tight models are available. The troughs are easily adaptable to collect materials from several infeed points and distribute materials through multiple intermediate gates. Flex mount conveyors install quickly and easily on concrete foundations or structures and require minimum maintenance.

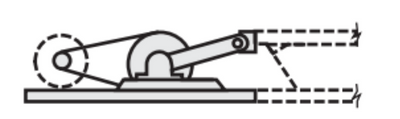

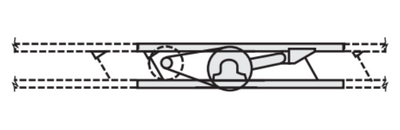

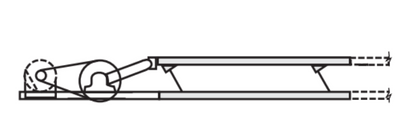

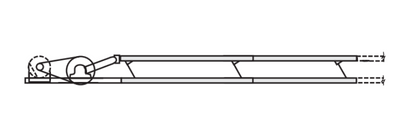

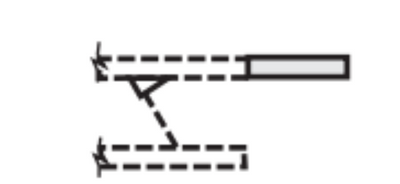

Flexmount trough assembly and positive drive Flexmount single drive for conveyor model 2500. Flexmount double drive for conveyor model 3500. Flexmount trough assembly Fiberglass leaf springs support the trough and material load and serve as a restoring energy system. This reduces the power consumption at operating speed. The fiberglass leaf springs are arranged in single, double, or triple configurations based on the length and width of the conveyor. Flexmount positive drive The Flexmount conveyor’s positive drive system has heavy-duty spherical roller bearings, a cast steel connecting arm, and a rubber-bushed or bronze wrist pin assembly, which is securely locked to the conveyor pan with taper lock bushings. This drive system maintains positive action regardless of load conditions. Drives are positioned either at the conveyor feed end (end drive) or along the conveyor length (intermediate drive). For the intermediate drive, the motor and motor supports are independent of the conveyor base and can be purchased with the unit. Motors for intermediate drives can be mounted on either the left hand or right hand side of the conveyor. Single-arm drives are used for 8- through 12-inch trough widths. Double-arm drives are normally used on conveyors with 18-inch or wider troughs.

Flexmount components, capacities and dimensions

Includes drive base, eccentric drive, drive bracket,

V-belt drive with guard. Optional motor and motor starter are

purchased separately.

Includes drive base, eccentric drive, 5-foot trough assembly

with end plate, V-belt drive with guard. Flexmount legs and

necessary bolts and nuts for connecting to conveyor are

included. Optional motor and motor starter are purchased

separately.

Includes trough, base, 2 sets of Flexmount reactor springs and

necessary bolts and nuts for connection to drive assembly or

adjacent sections

Includes trough, base, 3 sets of Flexmount reactor springs and

necessary bolts and nuts for connection to end drive assembly or

adjacent sections.

Includes trough, base, 2 sets of Flexmount reactor springs and

necessary bolts and nuts for connection to drive assembly or

adjacent sections.

Includes discharge and flared in feed extensions. Required bolts

and nuts included.

Used to extend discharge beyond base. Required bolts and nuts

included. Maximum length of 24-inches is available.

Used for dust-tight applications. Provided in 5-foot

sections. Required clamps or bolts for attachment to standard

trough section and sponge rubber gasket are included.

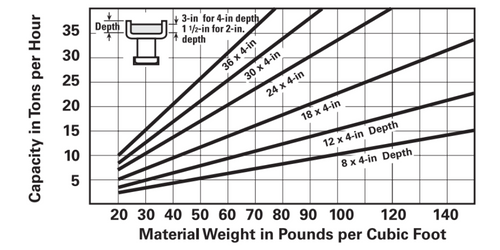

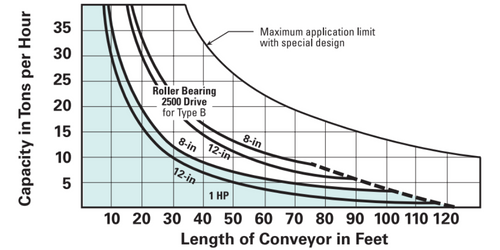

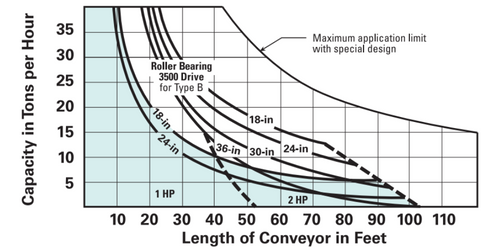

Flexmount Conveyor Capacities

To determine the proper conveyor width

required from Chart A, intersect conveyor

capacity in tons per hour with material

weight in pounds per cubic foot.

To determine the correct drive system

required from Charts B and C, intersect

conveyor capacity in tons per hour with the

required length of conveyor.

Flexmount components, capacities and dimensions, cont’d

|

Trough Size width x depth A x B |

C |

D |

G | J | K |

L |

M |

N

End drive only Model |

P |

|||||||

| Inter- mediate drive | End drive

Model |

Inter- mediate drive | End drive Model | Inter- mediate drive | End drive Model | |||||||||||

| 2500 | 3500 | 2500 | 3500 | 2500 | 3500 | 2500 | 3500 | |||||||||

| 8 x 4 | 5 5/8 | 10 1/2 | 9 1/2 | 9 1/2 | — | 10 1/4 | 10 1/4 | — | 15 3/4 | 15 3/4 | — | 9 1/2 | 10 | 44 9/16 | — | — |

| 12 x 4 | 5 5/8 | 14 3/4 | 9 1/2 | 9 1/2 | — | 10 1/4 | 10 1/4 | — | 15 3/4 | 15 3/4 | — | 9 1/2 | 10 | 44 9/16 | — | — |

| 18 x 4 | 5 5/8 | 20 3/4 | 15 1/2 | 9 1/2 | 15 1/2 | 15 1/4 | 10 1/4 | 15 1/4 | 16 1/4 | 15 3/4 | 14 3/4 | 9 | 10 1/2 | 44 9/16 | 44 1/4 | — |

| 24 x 4 | 5 5/8 | 26 3/4 | 15 1/2 | 9 1/2 | 15 1/2 | 15 1/4 | 10 1/4 | 15 1/4 | 16 1/4 | 15 3/4 | 14 3/4 | 9 | 10 1/2 | 44 9/16 | 44 1/4 | — |

| 30 x 4 | 5 5/8 | 32 3/4 | 19 1/2 | 9 1/2 | 15 1/2 | 19 1/4 | 10 1/4 | 15 1/4 | 16 1/4 | 15 3/4 | 14 3/4 | 9 | 10 1/2 | 44 9/16 | 44 1/4 | 11 5/8 |

| 36 x 4 | 6 1/8 | 38 3/4 | 22 1/2 | 9 1/2 | 15 1/2 | 22 1/4 | 10 1/4 | 15 1/4 | 16 1/4 | 15 3/4 | 14 3/4 | 9 | 10 1/2 | 44 9/16 | 44 1/4 | 14 5/8 |

| 48 x 4 | 6 1/8 | 50 3/4 | 27 1/2 | 9 1/2 | 15 1/2 | 27 1/4 | 10 1/4 | 15 1/4 | 16 1/4 | 15 3/4 | 14 3/4 | 9 | 10 1/2 | 44 9/16 | 44 1/4 | 19 5/8 |

Coil Mount vibrating conveyors

Syntron Coil Mount Oscillating Conveyors by DPH Engineering are ideally suited to convey a variety of materials including granular, free-flowing materials, fragile or sticky materials, and abrasive materials such as ores, sand, castings, and scrap metal.

Ruggedly constructed to provide reliable and economical service, the units can also be modified to suit specific scalping, cooling, heating, and drying processes. The Coil Mount handles large capacities of low- to high-density materials. Coilmount conveyors can be quickly and easily installed on concrete foundations or on structures near grade level. These conveyors are available in standard sizes of 10-inch and 20-inch widths with 6- inch deep troughs. A 12-inch deep trough is also available. Coilmount conveyors are constructed of either 10 gauge or 3/16-inch mild or stainless steel. In addition, flanged troughs can be made of special materials. A variety of liner materials are available for handling corrosive or abrasive materials. Troughs can also be furnished with covers that attach with bolts or quick-acting fasteners. Installing gaskets between the cover and trough creates a seal for dust tight or weather-tight applications. Inlet spouts and exhaust vents can also be provided to meet specific conveying processes.

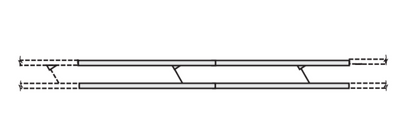

Coil Mount trough assembly and positive drive

Type A and B Coil Mount trough assembly The conveyor trough is supported by rubber-bushed aluminum stabilizer legs. Heavy-duty coil springs are used as a restoring energy system, providing reduced power consumption at operating speed. Single-spring reactor systems are furnished for 10-inch widths, and double-spring reactor systems are used for 20-inch widths. Type A and B Coil Mount drive The Coil Mount conveyor’s positive drive system has heavy-duty spherical roller bearings, a cast steel connecting arm, and a rubber-bushed or bronze wrist pin assembly, which is securely locked to the conveyor pan with taper lock bushings. This drive system maintains positive action regardless of load conditions. Drives are positioned either at the conveyor feed end as an end drive or along the conveyor length as an intermediate drive. For the intermediate drive, optional motor and motor supports are independent of the conveyor base and can be purchased with the unit. Motors for intermediate drives can be mounted on either the left-hand or right-hand side of the conveyor.

Type A Coil Mount components, capacities, and dimensions

Type A Coil Mount Conveyor Components

At DPH Engineering, we are aware of how important high-quality, dependable machinery that is performing at its best is to your bottom line. Because of this, we are dedicated to providing value to our consumers before, during, and after the sale. Your happiness is our first focus. On us, you can completely rely.

For more details on our products, contact us today!