BF-Series feeders are a type of electromagnetic vibratory feeder that is commonly used in industrial applications to feed bulk materials in a controlled and consistent manner. They work by using electromagnetic vibrations to move the materials through a trough or chute, which are created by an electromagnetic coil powered by an AC or DC power source. The vibrations can be adjusted to control the rate at which the materials are fed. These feeders are known for their high efficiency and reliability and are often used to feed materials such as powders, granules, and pellets. They are often used in industries like food processing, pharmaceuticals, and chemicals, due to their durability and reliability.

BF-Series feeders are a type of electromagnetic vibratory feeder that is commonly used in industrial applications to feed bulk materials. They are known for their high efficiency and reliability and are often used to feed materials such as powders, granules, and pellets in a controlled and consistent manner.

BF-Series feeders work by using electromagnetic vibrations to move the materials through a trough or chute. These vibrations are created by an electromagnetic coil that is powered by an AC or DC power source. The vibrations cause the materials to move along the trough or chute and can be adjusted to control the rate at which the materials are fed.

One of the key advantages of BF-Series feeders is their high efficiency. Because they use electromagnetic vibrations to move the materials, they are able to handle materials at a high rate of speed, which can significantly increase production rates. Additionally, because the vibrations are created by an electromagnetic coil, the feeders are able to handle materials that are difficult to feed with other types of feeders, such as powders and fine granules.

Another advantage of BF-Series feeders is their durability and reliability. These feeders are built to withstand the rigors of industrial use and are often made of high-quality materials that are resistant to wear and tear. Additionally, because they are powered by an AC or DC power source, they do not require any mechanical parts, which reduces the likelihood of mechanical failure.

Overall, BF-Series feeders are an excellent choice for industrial applications that require the efficient and reliable feeding of bulk materials. Their high efficiency, durability, and reliability make them well-suited for a wide range of industries, including food processing, pharmaceuticals, and chemicals.

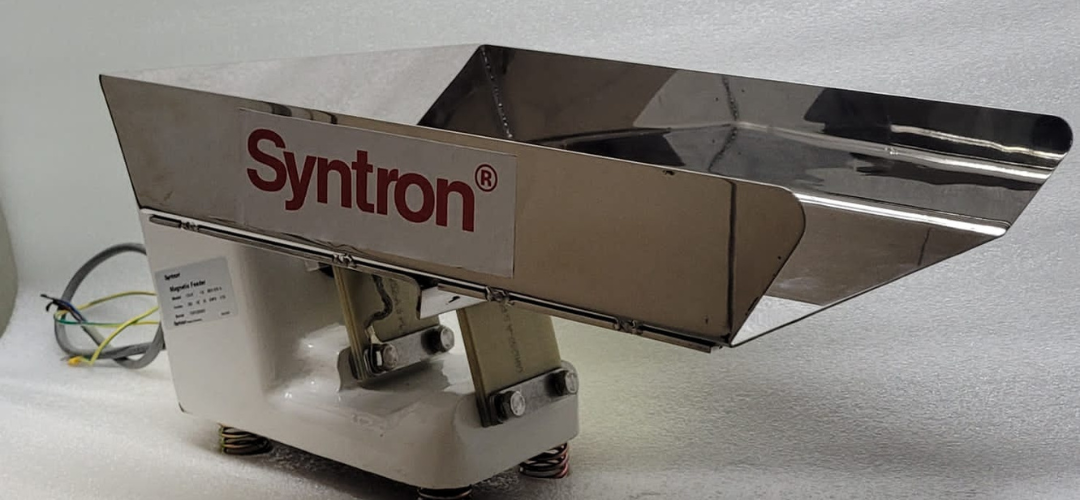

There are four Dph Engineering Syntron BF Vibrating Feeder models to choose from. These can be ordered with or without troughs.

Models

BF-01 gives you maximum feed control through instantaneous material flow cut-off. Rated at a maximum capacity of 5 tons per hour, when equipped with a standard 6″ x 24″ trough. Other trough types and sizes are available. Since the electromagnetic drive is both dust-proof and splash-proof, it can be cleaned with steam or water without damaging the electrical components.

| Trough Type | A | B | C | D | E | F | G | H | J | K | L | M | |

| Std. Flat Pan | (in) | 6 | 24 | 15 5/16 | 2 | 9 11/16 | 6 9/16 | 10 3/4 | 6 11/16 | – | 6 9/16 | 3 1/8 | 9/16 |

| (mm) | 152 | 610 | 389 | 51 | 246 | 167 | 273 | 170 | – | 167 | 79 | 14 | |

| Spec. Flat Pan | (in) | 5 | 20 | 13 5/16 | 2 | 9 11/16 | 6 9/16 | 10 3/4 | 6 11/16 | – | 6 9/16 | 3 1/8 | 9/16 |

| (mm) | 127 | 508 | 338 | 51 | 246 | 167 | 273 | 170 | – | 167 | 79 | 14 | |

| Spec. Flat Pan | (in) | 8 | 20 | 13 5/16 | 2 | 1011/16 | 6 9/16 | 10 3/4 | 711/16 | – | 6 9/16 | 3 1/8 | 9/16 |

| (mm) | 203 | 508 | 338 | 51 | 271 | 167 | 273 | 195 | – | 167 | 79 | 14 | |

| Spec. Flat Pan | (in) | 10 | 20 | 13 5/16 | 2 | 1011/16 | 6 9/16 | 10 3/4 | 711/16 | – | 6 9/16 | 3 1/8 | 9/16 |

| (mm) | 254 | 508 | 338 | 51 | 271 | 167 | 273 | 195 | – | 167 | 79 | 14 | |

| Spec. Flat Pan | (in) | 12 | 14 | 9 1/16 | 2 | 1011/16 | 6 9/16 | 10 3/4 | 711/16 | – | 6 9/16 | 3 1/8 | 9/16 |

| (mm) | 305 | 356 | 230 | 51 | 271 | 167 | 273 | 195 | – | 167 | 79 | 14 | |

| Spec. Tubular | (in) | 3 dia | 24 | 15 5/16 | – | 10 5/8 | 6 9/16 | 10 3/4 | 6 5/8 | 7 sq | 6 9/16 | 3 1/8 | 9/16 |

| (mm) | 76 | 610 | 389 | – | 270 | 167 | 273 | 168 | 178 | 167 | 79 | 14 | |

| Spec. Tubular | (in) | 4 dia | 20 | 9 13/16 | – | 11 5/8 | 6 9/16 | 10 3/4 | 6 5/8 | 8 sq | 6 9/16 | 3 1/8 | 9/16 |

| (mm) | 102 | 508 | 249 | – | 295 | 167 | 273 | 168 | 203 | 167 | 79 | 14 |

BF-2 offers the same innovative features as the smaller BF-01, but with a higher feeding capacity of 7-1/2 tons per hour when equipped with a standard 8″ x 30″ trough. Other trough types and sizes are available.

Model BF-3

The Dph Engineering Syntron BF-3 feeder is an exciting new addition to Syntron Material Handling’s existing line of products by offering a single drive solution for larger trough sizes. The BF-3 utilizes a sealed, sanitary design capable of handling a diverse range of feeding applications while providing solutions for industries such as food, pharmaceutical, material handling, and packaging.

Features

Designed for high speed feeding up to 60 ft per minute

• Sanitary design eliminates contamination during washdown

• Drive design is IP 66 compliant

• CSA Approved and CE Incorporable

• Feeder capable of operating at .090” stroke with a trough carrying weight ranging from 20 to 40 pounds

•Other trough sizes available – contact the factory for assistance

• Externally adjustable tuning

| Trough Type | A | B | C | D | E | F | G | H | J | K | L | |

| Std. Flat Pan | (in) | 12 | 42 | 28 15/16 | 4 | 16 5/16 | 10 | 161/16 | 11 5/16 | 7 1/2 | 7 3/4 | 1 3/16 |

| (mm) | 305 | 1,067 | 735 | 102 | 414 | 254 | 408 | 287 | 191 | 197 | 30 | |

| Spec. Flat Pan | (in) | 8 | 48 | 3115/16 | 4 | 16 5/16 | 10 | 191/16 | 11 5/16 | 7 1/2 | 7 3/4 | 1 3/16 |

| (mm) | 203 | 1,219 | 811 | 102 | 414 | 254 | 484 | 287 | 191 | 197 | 30 | |

| Spec. Flat Pan | (in) | 10 | 48 | 3115/16 | 4 | 16 5/16 | 10 | 191/16 | 11 5/16 | 7 1/2 | 7 3/4 | 1 3/16 |

| (mm) | 254 | 1,219 | 811 | 102 | 414 | 254 | 484 | 287 | 191 | 197 | 30 | |

| Spec. Flat Pan | (in) | 10 | 38 | 24 15/16 | 4 | 16 5/16 | 10 | 161/16 | 11 5/16 | 7 1/2 | 7 3/4 | 1 3/16 |

| (mm) | 254 | 965 | 633 | 102 | 414 | 254 | 408 | 287 | 191 | 197 | 30 | |

| Spec. Flat Pan | (in) | 12 | 48 | 31 15/16 | 4 | 16 5/16 | 10 | 191/16 | 11 5/16 | 7 1/2 | 7 3/4 | 1 3/16 |

| (mm) | 305 | 1,219 | 811 | 102 | 414 | 254 | 484 | 287 | 191 | 197 | 30 | |

| Spec. Flat Pan | (in) | 14 | 30 | 21 15/16 | 4 | 16 5/16 | 10 | 1515/16 | 11 5/16 | 7 1/2 | 7 3/4 | 1 3/16 |

| (mm) | 356 | 762 | 557 | 102 | 414 | 254 | 405 | 287 | 191 | 197 | 30 | |

| Spec. Flat Pan | (in) | 16 | 30 | 12 15/16 | 4 | 16 5/16 | 10 | 1515/16 | 11 5/16 | 7 1/2 | 7 3/4 | 1 3/16 |

| (mm) | 406 | 762 | 329 | 102 | 414 | 254 | 405 | 287 | 191 | 197 | 30 |

Benefits and Features of the BF-3

- Feeding capacity of 25 tons per hour, when equipped with a standard 12″ x 42″ trough (optional)

- Designed for high-speed feeding up to 60 ft per minute

- Feeder capable of operating at .090″ stroke with a trough carrying weight ranging from 20 to 40 pounds

- Sanitary design, eliminates contamination during wash-down

- Drive design is IP 66 compliant

- CE and CSA certified

- Other trough sizes available – contact the factory for assistance

- Externally adjustable tuning

- Compatible with Conductor 15 Control

BF-4 and BF-4-LF

Combine electromagnetic reliability and a low profile, compact design with a long enough trough overhang and high product feed rate, and you have the foundation for an exceptional vibratory feeder. You’ll find all these advantages and more with FMC’s Syntron BF-4 Vibrating Feeder. The BF-4 provides fast, accurate, yet gentle feeding of a wide range of bulk materials from food products such as snacks and vegetables to other materials such as plastics and chemicals.

Because of its versatile design, the BF-4 is ideal for feeding various types of packaging and processing equipment, such as multi-head weigh scales and filling machines. It can also be used in modular distribution systems for transfer feeding. The BF-4 has a long trough overhang that reduces product degradation by allowing the feeder discharge to be positioned as close to the scale or transfer point as possible, thus minimizing product drop.

By incorporating a fully-adjustable stroke — up to .160 inches (4 mm) — the BF-4 easily handles difficult-to-feed products such as gummy candies, shredded lettuce, and wet vegetables. It can achieve product travel speeds up to 50 feet (15 meters) per minute. It’s simple, low-profile drive is an excellent solution for applications where space is limited; a single drive packs enough power to drive throughs up to ten feet long.

The Syntron BF-4 Feeder is also ideal for feeding, mixing, blending, batching, and grinding applications, as well as for packaging and cold room applications. Continuous welds on stainless steel troughs provide extra sanitation for FDA or USDA applications.

- Trough: 6″x24″x2″D Long Flat, Mild Steel

- Dimensions: 7″Wx26″Lx10″H

- Max Capacity: 5 Tons/Hour

- Shipping Weight: 60 lbs.

- 115V/60H

Additional information

| WEIGHT | 65.00 lbs |

|---|---|

| SIZE | VIB BF-2 115V/60Hz, VIB BF-2 230V, VIB BF-3 115V/60Hz, VIB BF-3 230V, VIB BF-4 230V, VIB BF-4A 115V, VIB BF01 115V/60Hz, VIB BF01 230V, VIB BF-2NT 115V/60Hz, VIB BF-3T 115V/60Hz |