Belt Conveyors and their Components

What is a Belt Conveyor?

Since the nature of the things being moved varies, so does the belt material according to the system it is used in. It frequently appears as a rubber or polymer belt.

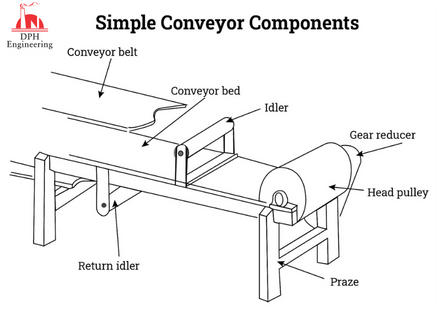

A typical belt conveyor system has a frame,

- Idler Rollers,

- Head Pulleys and

- Tail Pulleys,

- Troughing Idler

- Rubber Disk Idler

- Screw Idler Roller

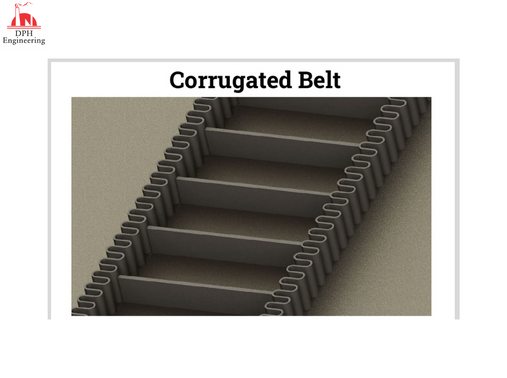

- Conveyor Belt, and Corrugated Belt.

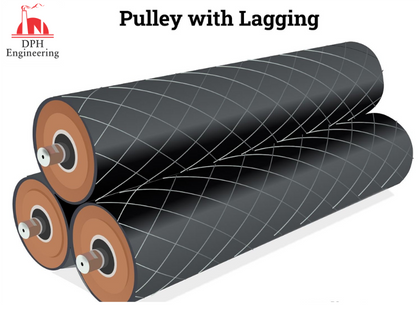

Head Pulley

The head pulley is a key part of a conveyor system, connected to the actuator and electric motor, and acts as the pulling force. The head pulley definition involves its position at the discharge end where the conveyor dumps its load. To improve grip, a rough jacket called a legging is added to it. The difference between head pulley and tail pulley is that the head pulley drives the belt, while the tail pulley guides it back, ensuring tension and alignment.

The diameter of the head pulley is usually the biggest of all the pulleys. In some systems, more than one pulley can act as a drive pulley. The head pulley is the drive roller with the biggest diameter that is at the end where the belt comes off.

Return or Tail Pulley

This is at the end of the belt conveyor where the goods are being loaded. It sometimes has a wing shape that lets material fall away from the belt and onto the support members, which cleans the belt.

In a simple belt conveyor, the tail pulley will be mounted on guides that usually have slots to let the tension of the belt pass through. In other belt-conveying systems, the tension of the belt is managed by another roller called the “take-up roller.” The difference between head pulley and tail pulley is that the head pulley drives and pulls the belt, while the tail pulley is at the loading end, providing tension and guiding the belt back.

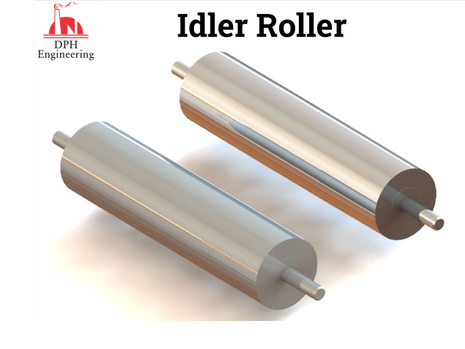

Idler Roller

These are rollers used to support the belt and load, prevent sagging, align the belt, and clear up carryback along the length of the belt (material left sticking on to the belt).

Idler rollers can perform any one of the aforementioned tasks or all of them, but they will always support the belt in whatever environment.

The following is a list of the various idler roller types available for various purposes:

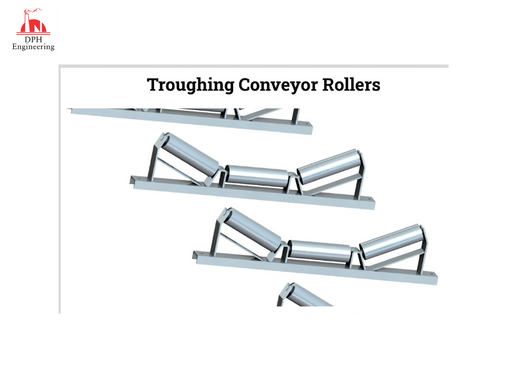

Troughing Idlers

Three idler rollers will be arranged in a way on troughing idlers that causes the belt to form a “trough.” They are situated on the side of the belt conveyor that is carrying the cargo. While the two on the ends can be modified, the idler in the centre is immovable. This allows for flexibility in the trough’s depth and angle. When these idlers are used, spillages will be decreased and the cross-sectional area of the belt conveyor will remain constant. Stability depends on maintaining a consistent cross-sectional area.

Rubber Disk Idler

Rubber discs are positioned along the roller axis of this idler at predetermined intervals. In order to reinforce the belt edge, which is prone to tearing, the rollers are significantly closer together at the extreme ends. The evenly spaced discs will separate any associated carryback or leftover material and lessen material accumulation on the belt’s underside. This is a frequent reason for tracking errors (when the belt shifts to one side of the system and causes misalignment).

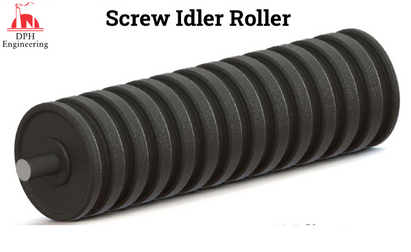

Screw Idler Roller

Sometimes the discs are shaped like a screw, and the idler is called a rubber screw idler roller. It will still do the same thing. A screw idler roller is shown in the picture below. Rubber helix can also be used to make the screw idler. Most of the time, screw idlers are used where a scrapper that gets rid of carryback wouldn’t work, like on mobile belt conveyors.

Trainer Idler

Trainer idlers make sure the belt goes in the right direction. It keeps you from getting lost. It does this with the help of a central pivot that turns the roller back to the middle if the belt moves to the side. It also has two guide rollers that help keep the belt in place.

Conveyor Belt

The belt is the most complex part of a belt conveyor setup, requiring the right tension and strength to handle heavy loads. Longer transport needs have led to the development of stronger, eco-friendly belts, but they are often expensive. Cheaper belts can break easily, leading to high operating costs. Ideally, the belt cost should be less than half of the total conveyor cost.

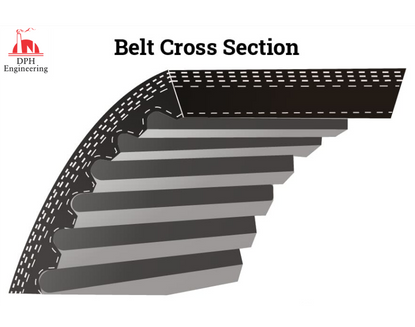

Some of the parts of a belt are:

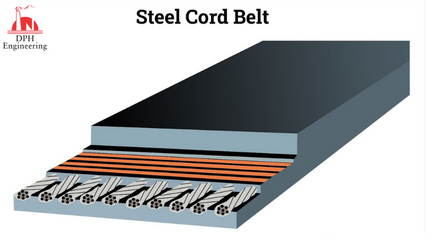

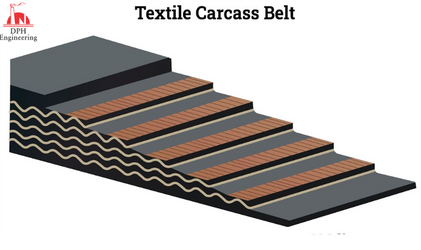

Conveyor Carcass

Since this is the belt’s skeleton, it needs to have the tensile strength to move the belt and the lateral stiffness to support the load. It must also be able to absorb the force of a load. The belt is a loop, so it needs to be joined. This is called splicing. Some methods of splicing involve bolts and fasteners, so the carcass must be able to provide a solid base for these fasteners.

The frame is usually made of steel cord or textile ply. Textile ply is made of fibers like aramid, polyamide, and polyester. Even when there is only one ply, a PVC-coated textile carcass is often used. There can be even six layers of meat on a carcass. The carcass can also include the edge protection that is very important in bulk conveyor belts.

Conveyor Covers (Top and Bottom & Sides)

This is a flexible material made from rubber or PVC. The covers are exposed directly to the weather and the working environment. Depending on how the covers will be used, they need to be carefully chosen. Most of the time, you need to pay attention to flame resistance, low-temperature resistance, grease and oil resistance, anti-static, and food grade.

The side of the conveyor that carries the load, the angle at which the conveyor is tilted, and how the belt is used in general all have special features. It can be rigid, smooth, or cleated.

Steel belt conveyors are also used in places like scrap conveyors in CNC machines because they don’t wear out as quickly as other materials.

Belts made of PVC, PU, and PE are also used in the food processing industry to keep food safe and limit contamination.

Plastic belts have only been around for a short time, but they are slowly becoming more popular because they are useful in so many ways. They are easy to clean, can be used in a wide range of temperatures, and work well with viscosity. They can also handle saltwater and substances that are alkaline or acidic.

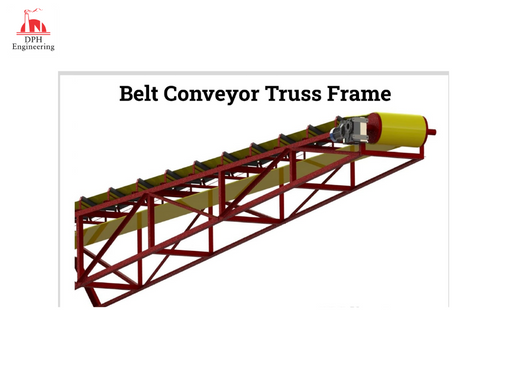

Conveyor Frame Design

The conveyor frame design varies based on the load capacity, height, and distance requirements. Conveyor frame components can be simple, like a cantilever, or more complex, like trusses, for heavier loads. Belt conveyor frame design also utilizes aluminum extrusions for lightweight and simple tasks.

The design of the frame is an important part of the design of a conveyor. If the frame isn’t made well, it can:

- Belt running out of track

- Structural failure which results in:

- Long downtimes which translate to delays in production

- Injuries and casualties

- Costly Spillages

- Expensive fabrication methods and installation.

On the frame, you can also attach things like walkways and lights, as shown above. In some lighting situations, the materials will need sheds and guards to keep them safe. Chutes for loading and unloading can also be attached. To avoid unplanned overloading, it’s important to know about all of these possible add-ins.

Types of Belt Conveyors

This section will talk about the different kinds of belt conveyors. Among these are:

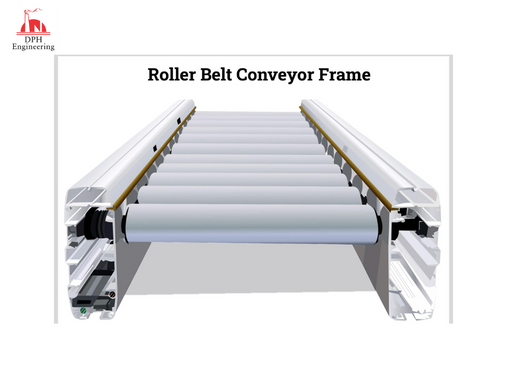

Roller Bed Belt Conveyor

This type of conveyor belt has a surface of rollers just under the belt. The rollers are close together, so there isn’t much sagging of the belt.

They are good for both long and short distance travel. In some cases, they can be so short that they only need two rollers for the whole system.

The roller belt conveyor is an effective way to load materials using gravity. However, if the rollers are loaded by hand, the shock can easily damage them due to the bearings inside. These bearings and the smooth surface of the rollers reduce friction, allowing easy movement. The roller belt conveyor design is ideal for applications where items are sorted, assembled, moved, or inspected manually. Common uses include:

- Airport baggage handling

- Sorting courier items, such as in post offices.

Flat Belt Conveyor

One of the most popular types of conveyors is the flat belt conveyor, commonly used for moving items within a building. For internal transportation, the flat belt conveyor design involves several motorized rollers and pulleys to pull the belt. The flat belt conveyor system uses belts made of fabrics, polymers, or natural rubber, allowing it to carry various materials.

- Slow-moving lines

- Wash-down applications

- Light, dusty environments.

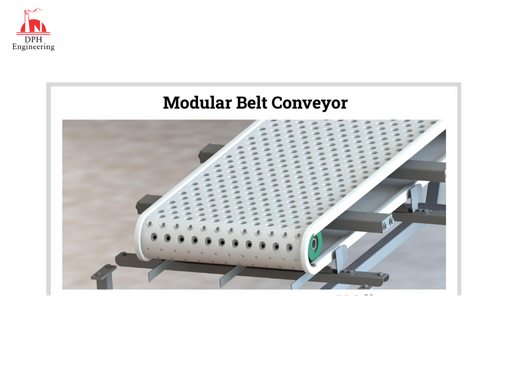

Modular Belt Conveyor

Modular belt conveyors use a series of rigid, interlocking pieces, unlike flat belt conveyors, which use a seamless loop of flexible belt. This modular belt conveyor design provides strength and versatility, allowing the conveyor to operate across various temperatures and pH levels. Damaged sections can be easily replaced, unlike with flexible belts, which require full replacement.

- Food handling

- Fluid handling

- Metal detection

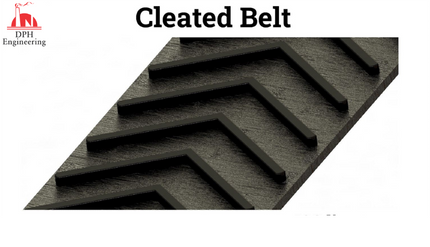

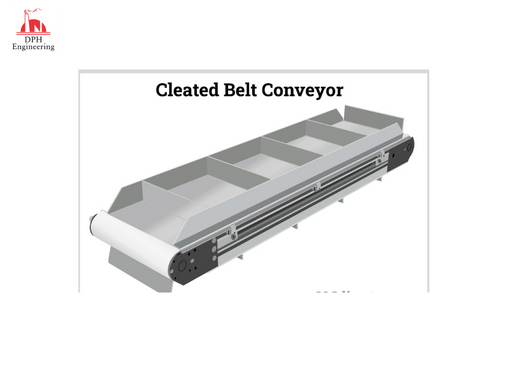

Cleated Belt Conveyor

Cleated belt conveyors are designed with stoppers or cleats that divide the belt into equal sections. This cleated belt conveyor design prevents particles and materials from rolling back or falling off as the conveyor moves up and down. The cleats on the cleated belt are essential for maintaining material flow and stability. Cleated belt conveyors are particularly effective in cleated belt conveyor systems where managing inclines and declines is crucial.

The cleats come in a variety of sizes and shapes, such as:

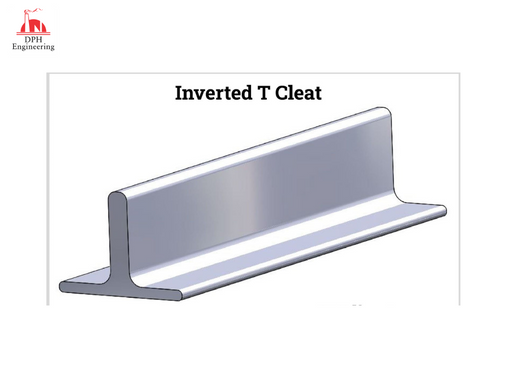

Inverted Capital T

This cleat will stand at a 90-degree angle to the belt to give fragile items support and movement. It works best for light jobs and moving small parts, packaged goods, and food.

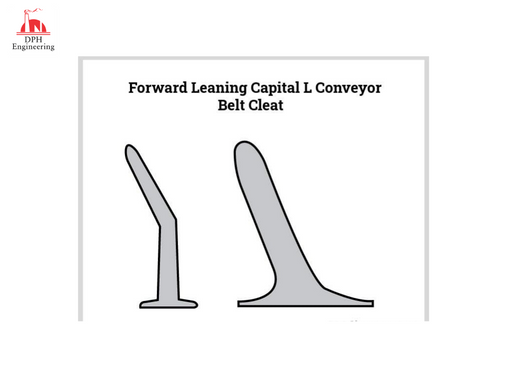

Forward- Leaning Capital L

Because of how it’s oriented, it can easily resist leverage forces. It can be used to scoop granules and hold them up against gravity. It can be used to hold light to medium-weight granules.

Inverted V Cleats

These cleats are less than 5 cm high, but they have the same effect as a trough. They can be used to move heavy or large amounts of material because their cleat is short and can withstand high impacts.

Lugs and Pegs

These cleats are used to help water run off after washing things like vegetables and fruits. Lugs and pegs are a cheap way to move things that don’t need to be held up the whole length of the belt, like big boxes or rods. They can also be used to move only products that are bigger than a certain size and even hold single products in place.

Cleated Belt Conveyors can also be used to:

Escalators are different from cleated belt conveyors in that they move loose items up a steep incline.

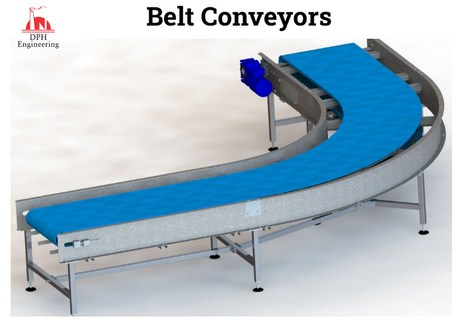

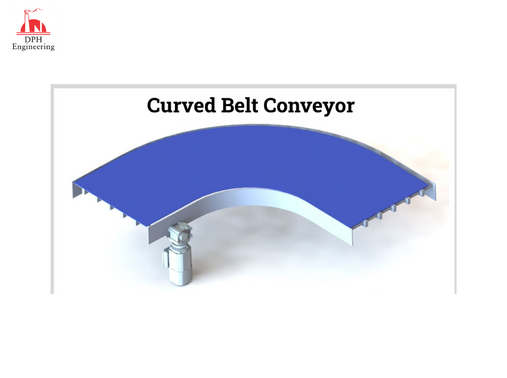

Curved Belt Conveyor

This conveyor features a frame that is pre-bent, allowing it to carry items around tight corners. It is ideal for areas with limited space where curved conveyor belt design helps save room. The curves can be as steep as 180 degrees. Modular plastics with interlocking pieces are used for conveyors with straight sections before the curve.

For conveyors with significant curvature, flexible flat belts are employed. How do curved conveyor belts work? They use specially designed frames and belts to navigate corners and bends smoothly. The curve belt conveyor design ensures efficient material handling in confined spaces.

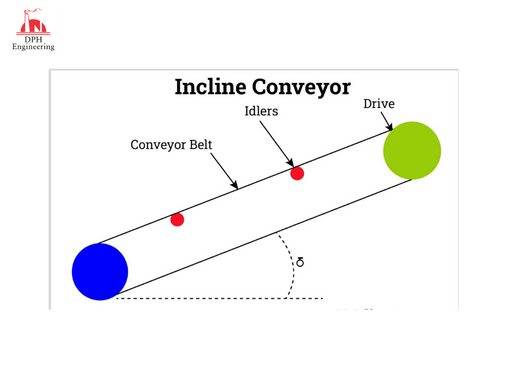

Incline/Decline Belt Conveyor

On inclined conveyors, keeping things from falling off the belt requires a tighter tension force, more torque, and traction on the belt surface. So, they will have a gear motor, a centre drive, and a take up. The belt must also have a rough surface to make it easier to grip.

Like cleat conveyors, these move objects up an incline without letting them fall off. They can also be used to speed up the way fluids move in response to gravity.

Sanitary Washdown Conveyor

Health and safety rules usually require sterilisation and rough washing in the pharmaceutical and food industries. Washdown and sanitary conveyors are made to handle these kinds of sanitary tasks. Most of the time, thin, flat belts are used in this setting.

Belt conveyors with sanitary wash-down stations are used for things that come from places like freezers and furnaces. They have to work sometimes in hot oil or glaze. Because they can work well in greasy places, they are sometimes used to get oil drums and crates off ships

Troughed Conveyors

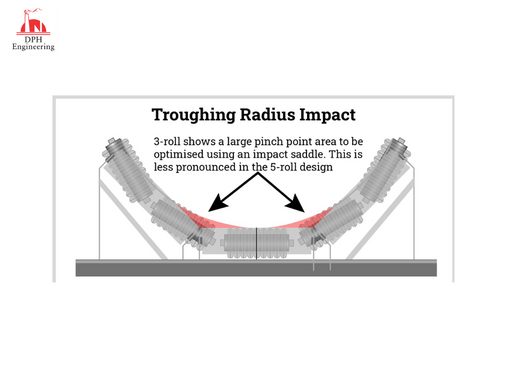

A troughing belt conveyor is not a separate type of belt, since troughing can be added to any type of conveyor.

It uses a belt that looks like a trough because the idler rollers under it are also shaped like a trough.

The centre roller of the troughing idler rollers has a horizontal axis of rotation, while the axes of the two outer rollers, called “wing rollers,” are tilted away from the horizontal. Most of the time, the angle is around 25 degrees. The top idler rollers are the only ones that get troughed; the bottom ones never really do.

Higher troughing angles will damage the belt in a way that can’t be fixed. If the belt is troughed at sharper angles, it will keep its cup shape and be hard to clean, hard to track, and might even break in the middle. It could also decrease the amount of surface contact with the idler rollers, which would make the belt conveyor system less effective.

Most of the time, trough belts only work in one plane, either horizontally or at an angle of up to 25 degrees. The belt must have a large enough radius so that it can still touch all of the rollers in the troughing idler. If the angle of the troughing is sharper, the belt won’t touch the centre idler roller. This weakens the belt’s structure and the overall efficiency of the conveyor system.

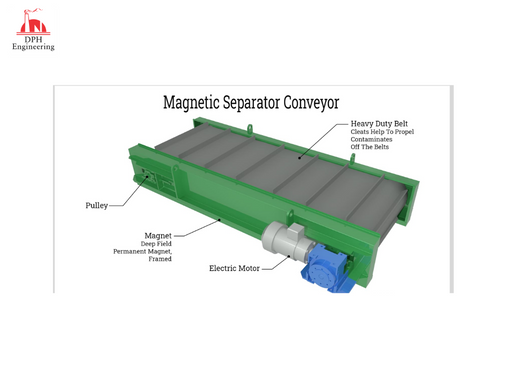

Magnetic Belt Conveyor

Magnetic belt conveyors use ferrite or neodymium magnets to move and control ferrous metal parts, making them ideal for small items that don’t fit on traditional conveyors. They operate similarly to regular belt conveyors but leverage the magnetic properties of materials. Magnets are spread along the conveyor bed, counteracting gravity. The adjustable strength of the magnets in magnetic conveying systems ensures effective handling regardless of material size.

Types of Magnetic Belt Conveyors

Magnetic Belt Conveyors: These are popular due to their simplicity, featuring a metal belt magnetized with permanent magnets or electromagnets to attract iron-based materials. They operate like regular belt conveyors but can move items vertically, up slopes, and even upside down.

Magnetic Separator Belt Conveyors:

These conveyors are designed to separate ore from dust and debris. Non-magnetic materials fall off the belt, while magnetic ones stick. They come in dry types, which don’t require wet materials, and wet types, which do.

Design and Selection of Belt Conveyors

When making a conveyor belt, the most important things to think about are:

- Choice of motor and gearbox

- Speed of belt

- Tension and take-up

- Material to be moved

- Distance to be moved

- Working conditions, such as temperature, humidity, and so on.

Motor and Gearbox Selection

To help choose the motor, you must first know how much pulling force the conveyor needs.

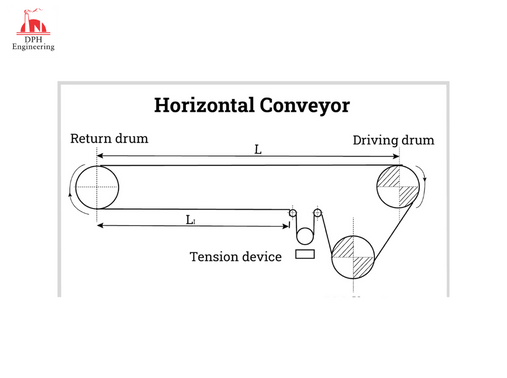

For a simple horizontal conveyor, the effective pulling force is given by the formula below:

Fu=µR · g(m+ mb+ mR)

Where:

Fu=Effective pulling force

µR =Friction Coefficient when running over roller

g = Acceleration due to gravity

m =Mass of goods conveyed on the whole length of the conveyor

mb =Mass of Belt

mR =Mass of all rotating rollers minus mass of drive roller

For a system on an incline, the effective Pulling force is given as below:

Fu=µR · g · (m + mb+ mR) + g · m · sina

Where

Fu =Effective Pulling Force

µR =Friction Coefficient when running over roller

g = acceleration due to gravity

m = mass of goods conveyed on the whole length of the conveyor

mb =Mass of Belt

mR =Mass of all rotating rollers minus mass of drive roller

a =Angle of inclination

Once the pulling force is known, it’s easy to figure out the torque and, from there, the right motor and gearbox.

Speed of Conveyor

The speed of the conveyor will be the circumference of the drive pulley multiplied by the revolutions per unit time.

Vc=D · F

Vc =Speed of conveyor belt in ms-1

D =Diameter of drive pulley in meters.

F =Revolutions of drive pulley per second

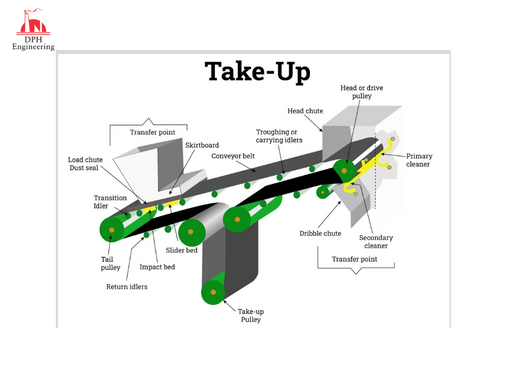

Tension and Take-up of the Belt

Take-up is an important part of keeping and getting the right amount of belt tension. This will make the process and its mechanical stability much better.

When the tension is right, the belt will wear evenly, keep the material in the trough evenly, and run in the middle when it goes over the idlers.

The length and width of every conveyor will always stretch a little bit.

Most of the time, it’s fine for a new belt to stretch by 2 percent more than its original length. Since this fraction will make the belt longer, there will be a slack in the whole belt. To keep the right amount of tension, this slack will have to be taken up.

The stretch will be bigger the longer a conveyor is. Using the 2 percent stretch, a belt that is 2 metres long can stretch by 40 mm, but a belt that is 200 metres long will stretch by 4 metres.

Take up is also a good idea when the belt needs to be fixed. In this case, the take-up is just let go, and it’s easy for the staff to do maintenance.

Types of Belt Conveyor Take-Ups

There are many ways to set up take-ups, and each has its own pros and cons. The most common types of belt conveyor take-up are the gravity take-up, the screw take-up, and the horizontal take-up.

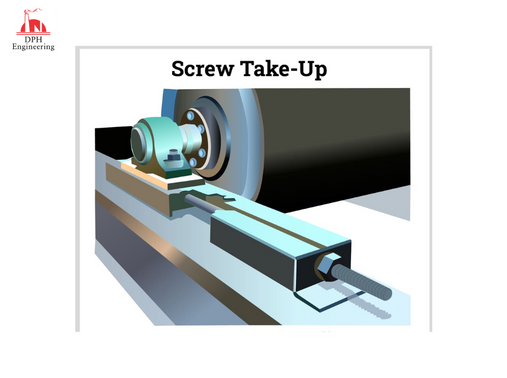

Screw Take-Up

The screw take-up takes up all the slack in the belt by using mechanical force. It does this by adjusting a threaded rod that is attached to one of the rollers, usually the tail roller. This threaded rod will be on each side of the roller, so it can also be used to get the roller in the right place. Since this method is done by hand, it is often called “manual take-up.”

The top angle take-up is a different style. Even though it is also popular, it needs a big, heavy tail frame to archive. The guards must also be big.

Screw take-ups are the easiest and most common way to control belt tension on short conveyors. They are inexpensive and work well.

Gravity Take-Up

Screw take-ups are usually not made to handle the length of the stretch that happens in conveyors longer than 100 metres. In these situations, the best way to tighten the belt is to let gravity do the work.

A gravity take-up assembly has three rollers. Two of them are bendy rollers, and the third is a gravity or sliding roller that controls the tension of the belt. A counterweight that will be attached to the gravity take-up roller pulls down on the belt to keep the tension from gravity. The bend rollers direct the slack in the belt around the gravity take-up roller.

The full take up assembly is built into the bottom of the frame of the conveyor and keeps the belt taut all the time. This self-tensioning system makes it easy for the take-up to adapt to sudden changes in tension or load.

So, the gravity take-up method always keeps the belt at the right tension and keeps it from getting damaged by sudden spikes in load or tension. Gravity tensioners don’t need as much maintenance as the screw take-up method because they can tighten themselves.

Most of the time, they need to be fixed when the belt has reached the end of its life. That’s when it will have stretched enough that the assembly will have gone as far as it can. When this happens, the conveyor belt will either need to be replaced or cut and vulcanized. Gravity take-up systems are also called automatic take-up systems because they adjust themselves.

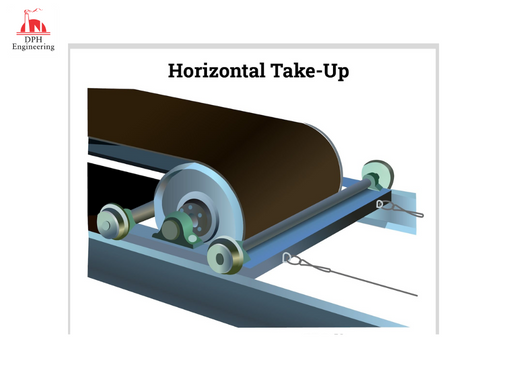

Horizontal Take-Up

The horizontal take-up can be used instead of the gravity take-up, but only when there isn’t enough room for both.

This take-up is similar to gravity take-up, but the assembly is placed vertically behind the tail roller instead of below the belt. This is especially helpful when the conveyor is on a slope and there isn’t any extra room under the conveyor.

Because the horizontal take-up won’t fall below the conveyor, a weight box is used to tighten the belt with a system of cables and pulleys. The cables that are attached to the tail pulley ride on a carriage that can be moved in and out of position.

Applications and Benefits of Belt Conveyors

These are examples of belt conveyor application, with significant relevance to the application of belt conveyors in India.

This chapter explores the conveyor belt application, benefits, common problems, their causes, and environmental impacts. It also covers types of conveyors and their applications.

Belt conveyors are versatile and used in various industries, including:

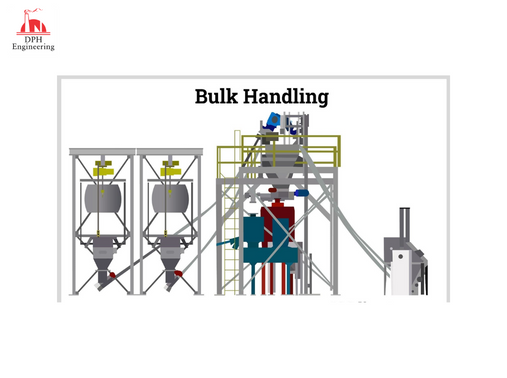

- Mining Industry: Bulk handling, processing plants, and transporting ores from shafts to ground level.

- Automotive Industry

These are examples of belt conveyor application, with significant relevance to the application of belt conveyors in India.

- Assembly line conveyors

- CNC machines’ scrap conveyors

- Transport and Courier Industry

- Baggage handling conveyors at airports

- Packaging conveyors at courier dispatch

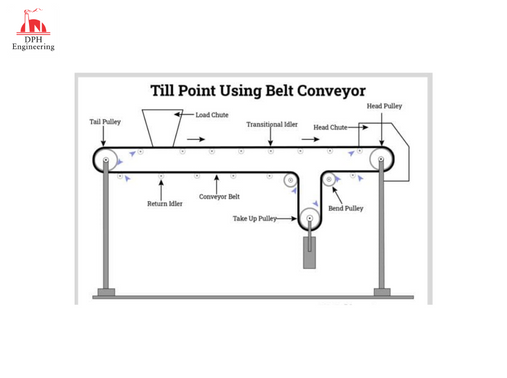

- Retailing Industry

- Warehouse packaging

- Till point conveyors

Other conveyor applications are:

- Food handling industries for grading and packaging

- Power generation conveying coal to the boilers

- Civil and construction as escalators

- Baggage handling conveyors at airports

- Packaging conveyors at courier dispatch

- Retailing Industry

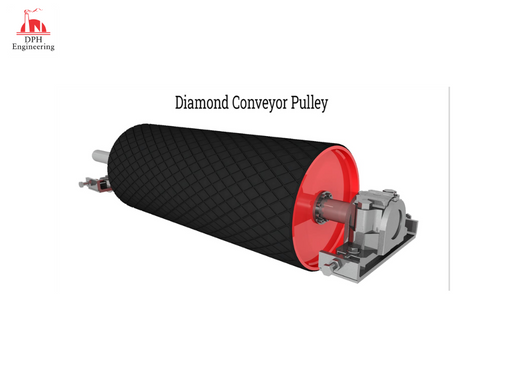

Types of Belt Conveyor Pulleys

Belt conveyor pulleys are essential components that keep the drive belt tight and direct its movement. They can be smooth, rubber-coated, or cast rubber, and come in various types, including drive, tension, motorized, snub, wing, and bend pulleys.

- Motorized Pulley or Motor Drum – Moves the conveyor belt with a sealed motor and protective drum, available in various sizes.

- Drive Pulley or Head Pulley – Moves the conveyor belt using a textured surface for friction, available in single or double-sided configurations depending on system size.

- Bend Pulley – Changes the belt’s direction, forming a loop, and is used as the tail roller in tensioning devices.

- Tension Pulley – Tightens the conveyor belt, solid and placed near the drive pulley to handle force.

- Snub Pulley – Enhances friction with the drive pulley, useful in high-power or contaminated environments.

- Wing Pulley – Cleans the return belt and provides excellent grip, available in various types like spiral and heavy-duty.

- Magnetic Pulley – Separates ferrous from non-ferrous materials using internal permanent magnets, suitable for magnetic conveyor belts.

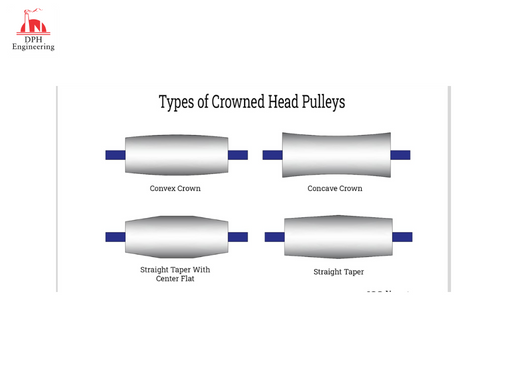

- Crowned Head Pulley – Features a cylindrical middle with tapered ends to stabilize the belt and keep it centered.

Advantages and Problems with Belt Conveyors

Most people think that belt conveyors are an easy and convenient way to move, sort, pack, and ship goods and products. They have been around for years in different forms and have made a huge difference in the efficiency of the supply chain.

Advantages of Belt Conveyors

The advantages of belt conveyors include:

- It is a cheap way of moving materials over long distances

- It doesn’t degrade the product being conveyed

- Loading can be done at any place along the belt.

- With trippers, the belts can offload at any point in the line.

- They do not produce as much noise as their alternatives.

- Products can be weighed at any point in the conveyor

- They can have long operating times can even work for months without stopping

- Can be designed to be mobile as well as stationary.

- Have less dangerous hazards to human injury

- Low Maintenance costs

Common Belt Conveyor Problems

Even though belt conveyors have their benefits, they are complicated pieces of equipment that need to be watched and managed. Among the things that need to be looked at are:

Problem 1: Conveyor Runs to One Side

Causes:

- Material buildup on idlers

- Misaligned idlers

- Tilted or uneven conveyor frame

- Uneven belt splicing

- Off-center loading

Problem 2: Conveyor Belt Slips

Causes:

- Poor traction between belt and pulley

- Stuck or non-rotating idlers

- Worn-out pulley lagging

Problem 3: Overstretching of the Belt

Causes:

- Over-tight belt tensioner

- Incorrect belt material selection

- Excessive counterweight

- Too long idler roll gaps

Problem 4: Excessive Edge Wear

Causes:

- Off-center loading

- High impact on the belt

- Belt rubbing against conveyor structure

- Material spillage

- Material trapped between belt and pulley

Environmental Effects on Belt Conveyors:

- Moisture: Causes rotting, cracking, loose adhesion, slippage, and rust on steel carcasses.

- Sunlight and Heat: Dry out and weaken rubber, cause cracking, and reduce belt tension.

- Cold: Stiffens the belt, making it harder to guide; can cause frost buildup, slippage, and ice clogs in chutes.

- Oil: Causes rubber to swell, lose tensile strength, and wear out faster.

Conclusion

A belt conveyor is a system designed to move materials, goods, and even people from one location to another. Unlike other methods that use chains, spirals, or hydraulics, a belt conveyor relies on a continuous belt to transport items. Understanding the belt conveyor design, including its components and parts such as conveyor belt sections and belt conveyor diagram, is crucial for optimizing its use. Knowledge of the conveyor belt system and its various components helps in efficient planning and maintenance.