In this blog, we will explore the working principle of vibrating screens, highlighting how they operate and the unique advantages they offer over other screening equipment. From improved material processing to reduced operational costs and maintenance, vibrating screens deliver efficiency and effectiveness that can significantly enhance productivity.

A vibrating screen machine is a device designed to sort materials based on their size. It consists of a frame with a screen or deck that shakes, powered by a motor. This shaking movement helps move the materials across the screen, allowing smaller particles to fall through while larger ones remain on top. These machines are widely used in industries like mining, agriculture, medicine, and construction to effectively separate and sort materials for further use.

Vibrating Screen Working Principle

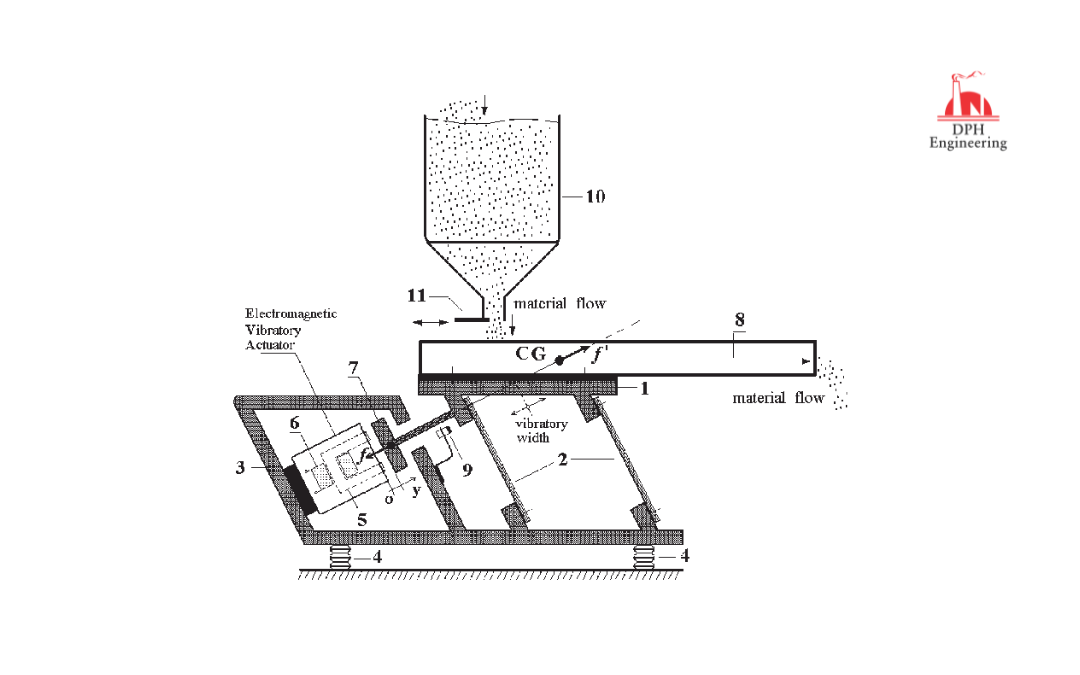

The vibrating screen working principle involves a machine that sorts materials into different sizes. It features a device that shakes back and forth, sending materials through several screens with various-sized holes. As the screen vibrates, smaller particles fall through these holes while larger ones stay on top. The screen can move in a circular motion or linearly, depending on its design. A motor connected to the screen generates vibrations by spinning a specially shaped weight. Vibrating screening machines can separate materials like sand, gravel, coal, and minerals. They are essential in industries such as chemicals, mining, and construction. The effectiveness of a vibrating screen depends on several factors, including the size and shape of the holes, vibration frequency, and screen angle.

The Benefits of Vibrating Screens

The advantages of vibrating screens include their importance in various industries such as waste management, recycling, and construction. They provide unique benefits that make them a preferred choice for many applications. This article explores how vibrating screens work and highlights their advantages over other screening machines.

What Is A Vibrating Screen?

A vibrating screen is designed to use vibrations to separate and sort particles by size. The key principle behind it is that vibrations reduce the surface tension between particles, causing them to move apart. Smaller particles, known as “fines,” fall through the screen, while larger ones remain on top and move across the surface. This method is particularly crucial in industries like mineral processing.

Whether you’re considering the best vibrating screen conveyor or exploring vibrating screen design, understanding the vibrating screen efficiency and its working principles is essential for optimizing your material sorting processes.

Vibrating screens offer several advantages over other types of material processing equipment, including:

- Improved processing and better quality of materials

- Lower operating costs

- Reduced maintenance and downtime

- More efficient screening

We’ll go into more detail about these benefits below.

Improved Processing and Material Quality

Vibrating screens offer several advantages in processing aggregate and mining materials, even though different types of screening equipment may be better for specific materials. Vibrating screens are particularly effective in meeting the fine separation needs of these industries. Their design generates the necessary force to separate larger particles from smaller ones, making it easier to recover the desired product, even when a much smaller size separation is needed. This leads to higher yields and overall better quality of the final product.

Lower Operational Costs

Vibrating screens are known for their strong build and affordability. They usually cost less than other types of screens because their simple design and operation make them easier to produce. This means companies have lower initial costs.

Moreover, vibrating screens use less energy compared to more complex machines, which helps reduce ongoing operating expenses. Since only the screen media needs regular replacement, businesses can save on maintenance and repairs that often come with other types of screening equipment.

Less Maintenance and Downtime

Repairs and maintenance can lead to significant losses in productivity and profit. Many screens wear out quickly, especially in demanding environments like aggregate processing. However, vibrating screens are easier to maintain and experience less downtime. Their design focuses on directing vibrations only to the screening surface, minimizing wear on other machine parts.

High-quality vibrating screens are designed to reduce the impact of vibrations on other components. Advanced designs can absorb excess vibrations, resulting in fewer moving parts and less overall wear and tear. This leads to lower maintenance needs and reduced downtime.

Higher Screening Efficiency

While many types of screening equipment are available, vibrating screens are the top choice for operations needing a simple solution that can handle high material flow. They perform best with a consistently high flow, preventing issues like clogging that can occur with other types of screens when processing the same amount of material.

Conclusion

In summary, vibrating screens play a crucial role in a variety of industries by effectively sorting materials based on size. Their unique design allows for efficient separation, ensuring that smaller particles pass through while larger ones remain on the surface for further processing. The benefits of using vibrating screens—improved processing and material quality, lower operational costs, reduced maintenance and downtime, and higher screening efficiency—make them an essential choice for businesses in mining, construction, recycling, and more.For further inquiries about integrating vibrating screens into your operations, feel free to reach out to us!

FAQs

How many types of vibration screens are there?

There are two main types of vibrating screens: circular and linear. Circular screens are always positioned horizontally, while linear screens can be horizontal or inclined. Both types can feature one, two, or three decks, which utilize wire mesh or perforated plates to separate products into the desired sizes or fractions.

What is the difference between a vibrating feeder and a vibrating screen?

A vibrating feeder moves materials and sorts them, while a vibrating screen separates materials by size. Screens are often used before crushers to ensure only the right-sized material goes in, whereas feeders focus on moving and sorting particles.

Related Blog –

How does a conveyor belt work

In this article, we’ll explore the workings of a conveyor belt by diving into its history, its various applications, and the advantages it brings to businesses today.

What is a Vibratory Feeder?

Vibrating feeders are essential components in material handling, with three main types: Electromagnetic Vibratory Feeders Natural Frequency

Belt Conveyors Components, Types, Design, and Applications

Are you thinking about getting a conveyor belt for your business? It’s important to pick the right one for your business needs.