Introduction

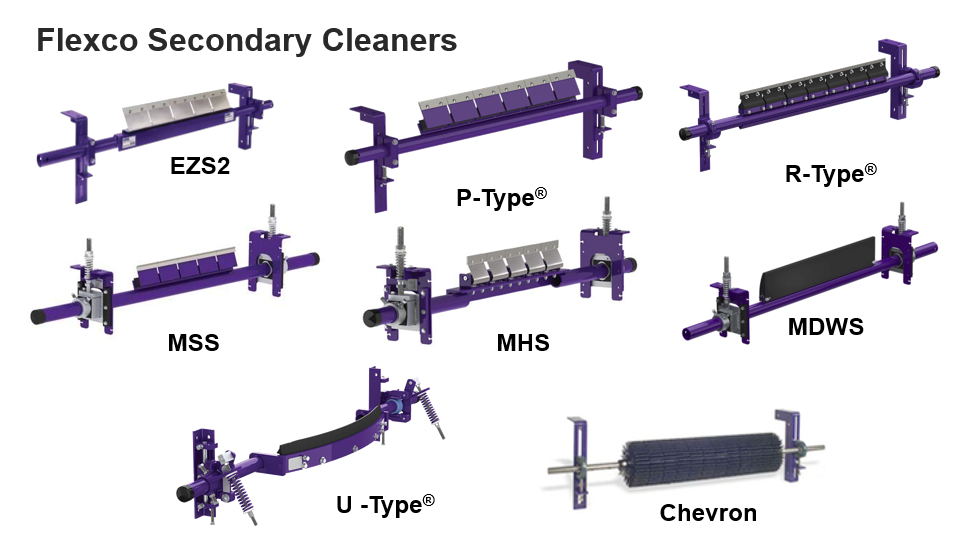

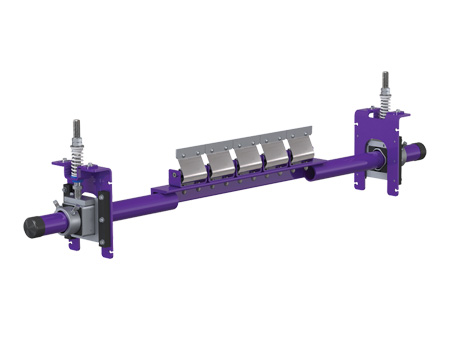

MHS HEAVY-DUTY SECONDARY CLEANER

The MHS Heavy-Duty Secondary Belt Cleaner was designed to deliver and maintain superior cleaning efficiency, even on the most demanding, abusive beltlines. It delivers high-efficiency cleaning and long lasting performance and is low maintenance.

Available with multiple tensioning options, all of our MHS cleaners were designed with features to make regular service easy, including the visual tension check. All service can be performed from a safe position at the side of the conveyor.

The Flexco Mineline® endorsement means it’s proven in heavy-tonnage applications that test the strength and durability of your conveyor system.

FEATURES AND BENEFITS

6″ (150 mm) segmented blades that are independently tensioned by our patent-pending PowerFlex™ cushions

Tungsten carbide blades deliver high cleaning efficiency and long wear life

Tips available for mechanically fastened or vulcanized belts

CEMA Class 5

Multiple tensioning options

Belt speeds up to 1500 fpm (6.0 m/sec)

Belt widths 18″ to 96″ (450 to 2400 mm)

INSTALLATION

Mounted after the head pulley

When the MHS is teamed with the MMP Precleaner, the system provides maximum cleaning power for tough applications

EZS2

18″ to 72″ (450 to 1800 mm)

EZS2 High-Temp

Belt Widths:

18″ to 72″ (450 to 1800 mm)

CBS CONTINUOUS BLADE SECONDARY CLEANER

The CBS Continuous Blade Secondary Belt Cleaner is designed with an unsegmented blade for excellent cleaning efficiency and low maintenance. The heavy-duty blade features a steel backbone holding a carbide leading edge which is encapsulated in our proprietary polyurethane to provide a long-wearing solution for your belt. When paired with a spring or air tensioner, the blade maintains constant pressure on the belt for excellent cleaning efficiency.

FEATURES & BENEFITS

Blade is a single, durable long-wearing front plate with urethane backing for streak-free cleaning

Thin, hard edge of the metal blade delivers high cleaning efficiency and long wear life

CEMA Class 4

SST XD tensioner for self-adjusting tension with easy retensioning adjustments and extra heavy-duty construction

Optional SAT XD Air/Water Tensioner

Belt speeds up to 800 fpm (4 m/sec)

Belt widths 18″ to 96″ (450 to 2400 mm)

INSTALLATION

Can be mounted 4″ (100 mm) from the transition point where the belt leaves the head pulley or any location down the beltline

When the CBS is teamed with the MMP precleaner, the system provides maximum cleaning power for tough applications

CBS Continuous Blade Secondary Cleaner

18″ to 72″ (450 to 1800 mm)

P-TYPE SECONDARY CLEANER

The DPH Engineering P-Type® Secondary Belt Cleaner is compact and designed to be positioned just off the head pulley to remove carryback from the belt. The P-Type can be used independently, or in conjunction with a precleaner, to form a highly efficient cleaning system.

The P-Type has a compact design with an additional LS model available with a smaller installation footprint. Also available with an Enhanced Service Advantage Cartridge for easy blade removal and replacement.

FEATURES AND BENEFITS

Segmented blades ensure proper wear throughout the life of the blade

Tungsten carbide blades deliver high cleaning efficiency and long wear life

Tips available for mechanically fastened or vulcanized belts

CEMA Class 4

Versatile tensioner kit can be mounted to push-up or pull-up the cleaner

Belt speeds up to:

C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Belt widths 18″ to 72″ (450 to 1800 mm)

INSTALLATION

Can be mounted 4″ (100 mm) from the transition point where the belt leaves the head pulley or any location down the beltline

When the P-Type is teamed with a precleaner the system provides maximum cleaning power for tough applications

P-Type

8 in. (200 mm)

2-3/8″ (60 mm) diameter pole

Belt Widths:

18″ to 72″ (450 to 1800 mm)

P-Type Limited Space (LS)

5-1/2 in. (138 mm)

2-3/8″ (60 mm) diameter pole

Belt Widths:

18″ to 54″ (450 to 1350mm)

P-Type with Enhanced Service Advantage Cartridge (ESAC)

Vertical clearance required:

Single: 10-1/2″ (267 mm)

Dual: 12-1/4″ (311 mm)

2-7/8″ (73 mm) diameter pole

Belt Widths:

24″ to 120″ (600 to 3000 mm)

R-TYPE REVERSING SECONDARY CLEANER

The DPH Engineering R-Type® Secondary Belt Cleaner is recommended for reversing belts and is designed to be positioned just off the head pulley to remove carryback from the belt. The R-Type can be used independently, or in conjunction with a precleaner, to form a highly efficient cleaning system.

It features two-way cushions that accommodate reversing belts used on shuttle conveyors, conveyors that roll back, or in tripper and stacker applications.

Available with an Enhanced Service Advantage Cartridge for easy blade removal and replacement.

FEATURES AND BENEFITS

Individually tensioned 6″ (150 mm) segmented blades for constant pressure and optimal cleaning

Tungsten carbide blades deliver high cleaning efficiency and long wear life

Tips available for mechanically fastened or vulcanized belts

CEMA Class 4

Versatile tensioner kit can be mounted to push-up or pull-up the cleaner

Belt speeds up to:

C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Belt widths 18″ to 72″ (450 to 1800 mm)

INSTALLATION

Can be mounted 4″ (100 mm) from the transition point where the belt leaves the head pulley or any location down the beltline

When the R-Type® is teamed with a precleaner the system provides maximum cleaning power for tough applications

R-Type

8 in. (200 mm)

2-3/8″ (60 mm) diameter pole

Belt Widths:

18″ to 72″ (450 to 1800 mm)

R-Type with Enhanced Service Advantage Cartridge (ESAC)

Vertical clearance required:

Single: 10 in. (254 mm)

Dual: 11-3/4 in. (298 mm)

2-7/8″ (73 mm) diameter pole

Belt Widths:

24″ to 120″ (600 to 3000 mm)

FMS MEDIUM-DUTY SECONDARY CLEANER

The FMS Secondary Belt Cleaner features carbide blades, self-adjusting spring tensioners and unique cushions that independently tension each blade to the belt. This simple, but durable, design provides quality cleaning performance at an affordable price. Its compact tensioner is a great choice for limited-space applications.

FEATURES AND BENEFITS

Segmented blades with unique sealed cushion design allows each blade to self-adjust and ensure proper wear throughout life of the blade

Tungsten carbide blades deliver high cleaning efficiency and long wear life

Tips available for mechanically fastened or vulcanized belts

CEMA Class 4

Compact MST spring tensioner with visual tension check

Belt speeds up to:

C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Belt widths 18″ to 72″ (450 to 1800 mm)

INSTALLATION

Can be mounted 4″ (100 mm) from the transition point where the belt leaves the head pulley or any location down the beltline

When the FMS is teamed with the MSP or MMP Precleaner the system provides excellent cleaning power for tough applications

FMS

18″ to 72″ (450 to 1800 mm)