Series

METALLIC BOX

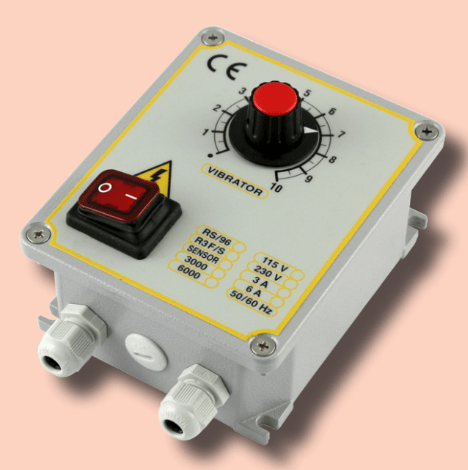

PV R4FC Z2 STM 140x115x60

METALLIC BOX

PV R4FC Z2 STM 140x115x60

METALLIC BOX

PV R4FC Z2 STM 140x115x60

CIRCUIT

PV R4FC A2 STD

DIMENSIONS

THIS OPERATING INSTRUCTION APPLY:

| Type | Box | Colour | Dimensions | Code |

| R4FC | Circuit | 94 X 117 X 33 | PV R4CXX A2 STD | |

| R4FC DIN | Circuit | 115 X 185 X 50 | PV R4CXX D2 STD | |

| R4FC | Fire-retardant plastic | RAL 7035 | 165 X 100 X 67 | PV R4CXX Z2 STD |

| R4FC | Aluminum | RAL 7035 | 140 X 115 X 60 | PV R4CXX Z2 STM |

| R4FC | Aluminum | RAL 7035 | 150 X 100 X 80 | PV R4CXX Z2 SM1 |

GUARANTEE

1) The controller is guaranteed for a period of 1 year from the date shown on the inside.

2) The guarantee covers the free replacement or repair of components parts that are defective

at origin for manufacturing errors.

3) The guarantee is not valid for damage caused accidentally due to improper use or negligence

and in case of alterations or repair carried out by unauthorized persons.

Design and specifications could be subjected to change without notice.

DECLARATION OF CONFORMITY

(EMC- Electromagnetic Compatibility)

and directive 2014/35/UE (LVD – Low Voltage Directive)

SAFETY INSTRUCTIONS

Indicates an immediate threatening danger.

Non-compliance with this information can result in death or serious personal injuries (invalidity).

Non-compliance with this information can result in death or serious personal injuries (invalidity).

Indicates a possibly dangerous situation.

Non-compliance with this information can result in damage to pro-perty or .light to medium personal injuries.

Indicates general notes, useful operator tips and operating recommendations which don’t affect safety and health of the personnel.

Before using the appliance it is necessary to read attentively the instructions included in this

technical sheet which provides you information about safety installation, use and maintenance.

keep this sheet safely for further information.

GENERAL INSTRUCTIONS

Before connect the equipment to the mains socket, make sure that the nameplate data match those of the mains power supply. Only use this equipment in accordance with the porpouse for which it is designed; i.e. for regolation of the amplitude of an electromagnetic vibrator feeder. Any other use is to considered improper, therefore hazardous.

The Manufacturer cannot be held liable for any improper, incorrect or unreasonable use of the equipment, switch it off and do not tamper with it. If repair is needed, please contact the Manufacturer’s Technical. Service Centre only, as they use original spare parts. Failure to observe the above the recommendations could impair the safety of the equipment.

All operations regarding adjustement, measurement and testing when required, must only be carried out by authorized and qualified personnel.

The Manufacturer shall accept no liability for damage to persons, animals or objects caused by work on the equipment carried out by unauthorized and unqualifield personnel.

Before switching on the equipment, connect the mains voltage, conforming to the current regulation, and the vibratory feeder.

Verifying that the installation has an appropriate ground wiring system.

TURN OFF THE POWER BEFORE OPENING.

working environment

If vibratory feeder works bad or doesn’t work:

- Check electric wires, to check regolation MIN/MAX.

- Swicht OFF voltage and to check the fuses and, this case, to check current MAX (ampere) in the vibrator.

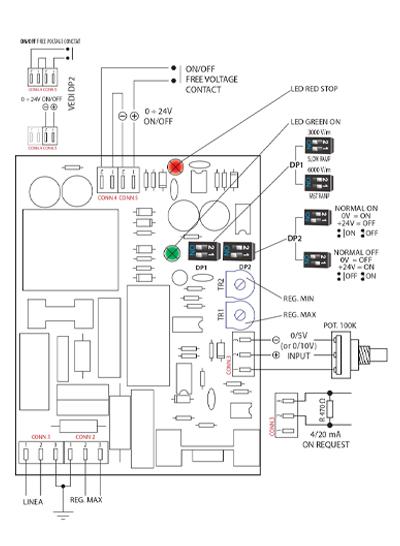

- Check DP2 (Normally ON)

TECHNICAL CHARACTERISTICS

- CIRCUIT TYPE: R4FC

- SUPPLY VOLTAGE: 115/230V ± 10% 50/60Hz

- CONSUMPTION: 1 W max

- CURRENT MAX: 4/5A (RMS)

- LOAD MIN.: 30mA RMS

- POTENTIOMETER OF REG.: 100K ohm linear

- FREQ. OF VIBRATION: 3000/6000V/m (50Hz)

- TIME RAMP: 0,1 sec. or 1 sec. (selectable)

- REGULATION MIN.: 80V ± 30%

- REGULATION MAX.: 200V – 30%

- INPUT ON/OFF: free contact – signal voltage 0-24Vcc

- DEGREE OF PROTECTION: IP55in box (only circuit IP00)

- DEGREE OF POLLUTION: 2 horizontal or vertical.

- TEMPERATURE OF STORAGE: -10 °C / + 80 °C

- TEMPERATURE OF OPERATION: -5 °C / + 55 °C

- RANGE OF RELATIVE HUMIDITY: 80% till to 31°C

- INSTALLATION CLASS: II

- ALTITUDE: till to 2000 meters

- EUROPEAN NORMS: EMC CE

- POSITION OF ASSEMBLAGE: horizontal or vertical.

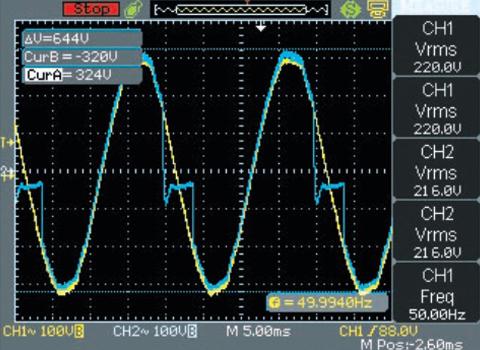

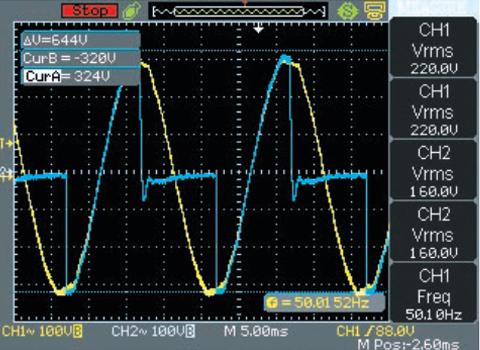

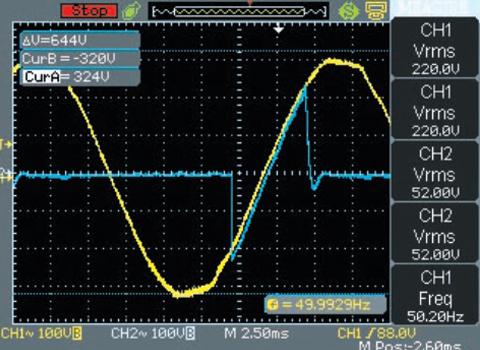

WAVE FORMS

- Supply controller (yellow)

- Output vibrator (blue)

- Frequency 50 Hz – 3000 V/m (Vibrator)

Fig. 1 : Output V/max 216V

Fig. 2 : Output V/medio 160V

Fig. 3 : Output V/min 52V

PARTICULAR INSTRUCTIONS

Before give voltage to the controller connect the supply voltage (clamps 1-2 CONN1), verifying

that the installation has an appropriate ground wiring system and the vibrator (clamps 2-3

CONN2) and (clamps 3 CONN1 and clamps 1 CONN2) GND – Led green ON.

According European Norms EMC the controller have a line-filter with leakage current to ground

less 1 mA.

To adjust intensity of vibration of the vibratory feeder, turn the adjustement knob (potentiometer

100K) on the box.

Regolation MIN/MAX

To adjust the Min./Max voltage of the vibratory feeder, proceed as follows :

MIN REG.: Turn the potentiometer to minimum, then set the minimum vibration by means of

relative trimmer TR2.

MAX REG. : Turn the potentiometer to maximum, then set the maximum vibration by means of

relative trimmer TR1.

N.B. : Use a small bladed screw driver in order not to damage the trimmer. Turn it in vertical

direction respect to the PC board.

Regulation 0/5V (0/10V-4/20mA)

Enter CONN3, (positive pin2 – negative pin3) with 0/5V signal (0/10V – 4/20mA with R470 Ω on

request).

Note: with 0V adjust the minimum, with 5V adjust the maximum.

The minimum is not affected by the maximum. The maximum is affected by the minimum.

ON- OFF

The vibratory feeder can be switched off (see CONN4-CONN5) by contact without voltage,

using the auxiliary ON/OFF input o signal voltage 0-24 VDC (1(-) and 2(+) CONN4) use DP2 for

logic 0/1 for both ON/OFF input.

Start Ramp

Is possible to change the time of the start ramp (slow 1 sec or fast 0,1 sec) by DP1.

3000/6000 V/m

Is possible to change the frequency of vibration 3000V/m-50Hz (3600V/m-60Hz) or 6000V/m-

100Hz (7200V/m-120Hz) by DP1; before switch off the voltage.

Double Speedy

Is possible (on request) to have nr.2 speed (hight and slow speed ) with 2 potentiometers (see

catalogue’s sheet DTCV2V)

| R3FC | R3FC–ISO | R3FSC | R3FSC-ISO | R5FC | R5FC-ISO | RS96C | CV99 | RV6 | |

| Voltage V 50/60 Hz | 115 o 230 | 115 o 230 | 115 o | 230115o230 1150 230 1150230115 0230 | 115 o 230 | 115 o 230 | |||

| Amps | 3 | 3/4 | 4 | 4/5 | 6 | 6 | 6 | 6 | 6 |

| ON/OFF Free Voltage | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ |

| ON/OFF Signal Voltage | – | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ |

| Sensor NPN/PNP | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | – | ⬤ | ⬤ |

| 0/10V 0/20 mA | – | – | – | – | – | – | – | ⬤ | ⬤ |

| Amplitude Regulation | Man. Pot. | Man. Pot. | Man. Pot. | Man. Pot. | Man. Pot. | Man. Pot. | Man. Pot. | Man. Pot. Autom. | Man. Pot. Autom. |

| Freq. Output 50/100 Hz 60/120 Hz | 3000/6000 3600/7200 | 3000/6000 3600/7200 | 3000/6000 3600/7200 | 3000/6000 3600/7200 | 3000/6000 3600/7200 | 3000/6000 3600/7200 | 3000/6000 3600/7200 | 3000/6000 3600/7200 | 3000/6000 3600/7200 |

| Slow/Fast Time Ramp | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ |

| Reg. Volt Min/Max | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ |

| EMC – CE | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ |

| Overload | – | – | ⬤ | – | ⬤ | – | ⬤ | – | – |

| IP | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 |

| Dimensions Box | 100x100x50 | 100x100x50 | 100x150x80 115x140x60 | 100x150x80 115x140x60 | 130x165x70 140x165x65 | 130x165x70 140x165x65 | 115x140x60 | 100x200x80 | 130x130x90 |

| DIN35 | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ |

| Photo | 1-2 | 2 | 3-6 | 3-6 | 4-5 | 4-5 | 6 | 7 | 8 |