Introduction

Quality and Performance

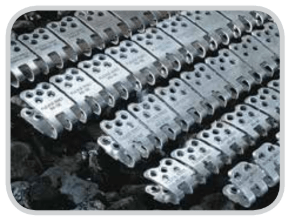

The Flexco SRTM Rivet Hinged Fastening System has earned a reputation for quality and performance in the most demanding material handling applications on earth. Wherever belt conveyors are used, you need a fastener system that lets you set up, splice, and get out of the way … fast. Flexco SR fasteners deliver the performance, long life, and easy installation that maximize belt availability and help keep productivity on a roll.

Maximum Splice Life, Increased Uptime

Flexco Rivet Hinged Fasteners combine top and bottom fastener plates, which are joined at one end by two wide hinge loops. Each pair of plates sandwich the belt end and are secured to the belt with a staggered pattern of rivets. The rivets penetrate the belt without damaging or weakening the belt carcass providing maximum resistance to pull-out and evenly distributed splice tension across the width of the belt. No matter what the belt condition, Flexco SR fasteners are a good choice for both new and older, worn belts. Rivet hinged fasteners can be used on belts ranging from 1/8″ to 1″ (3 – 25 mm) after skive with pulley diameters over 5″ (127 mm). Concerns about comparable vulcanized splice strength can be dismissed as rivet hinged fasteners have a long history of service on belts with mechanical fastener rating of up to 2000 P.I.W. (350 kN/m).

Market Applications

• Coal and Hard Rock

• Underground and Surface Mining

• Wood Processing

• Asphalt Plants

• Construction and Road Equipment

How the Flexco Rivet Hinged Fastening System Works

The SRTM (Self-Setting Rivet) Fastener utilizes staggered pattern, multiple rivet attachments that pass between carcass fibers without severing them. The specially shaped head of each pilot nail works in conjunction with the installation tool anvil plate to set the rivets. The same hammer blows that set the rivets also compress the fastener plates into the belt covers. This provides maximum holding ability and distributes splice tension evenly across the width of the belt.