Our Products

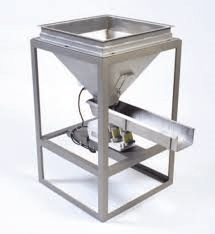

People have written a lot about how well Dph Engineering Syntron feeders work in the field of bulk material handling over the course of their more than 80 years of operation. Syntron feeders are subresonantly calibrated to ensure stroke uniformity and speed stability. This lets these feeders deliver larger capacities at controlled feed rates. Other standard features include a strong build, the ability to be tuned, and the ability to keep working well no matter how much headload is being put on it.

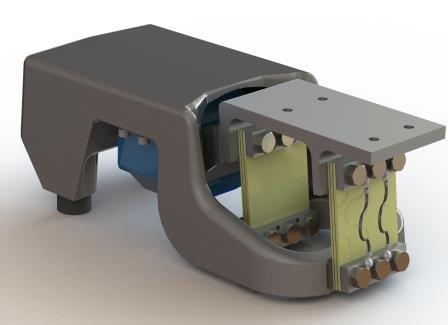

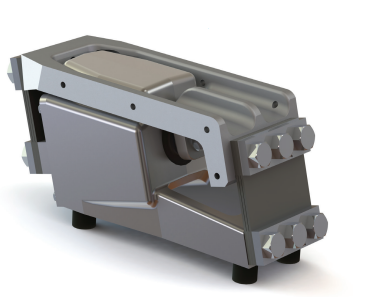

Syntron’s Vibrating Feeders are made with an electromagnetic design, which makes them very durable and reliable. Because there are no mechanical parts that can wear out or need to be oiled, breakdowns and the need for maintenance are very rare, especially in harsh or abusive environments.

The capacities range from 1,250 pounds per hour to 25 tonnes per hour, and they can be changed quickly to suit a wide range of specialised applications. The capacities are based on the fact that 100 pounds of granular material fill one cubic foot. Low-frequency models have a much larger amplitude, and they work at 1,800 vpm. All of the other types run at 3,600 cycles per minute on a 60 hertz power supply. All Syntron feeder models meet the OSHA noise limits so that they can be used in the food, pharmaceutical, and cosmetics industries. Also, they can be sent out in a way that meets FDA or USDA standards. For loads that have a lot of heavy things, there are different feeder options.

Changing the flow of materials is easy with a Syntron control. There are a lot of different ways to set up the controls, some of which are considered normal and some of which are considered unusual.