Bin Vibrators

Bin Vibrators, Hopper Vibrators Supplier, Pneumatic Vibration Motor suppliers in India

Electromagnetic Vibrators

The Dph Engineering Syntron Electromagnetic Vibrators are great for continuous or intermittent operation. The best and most variable flow of material is made possible by a control that is easy to change. Because there are no moving parts, Syntron Electromagnetic Vibrators are very reliable and require almost no maintenance. Most models come with a fully enclosed design that keeps out dust and water.

The Dph Engineering Syntron Electromagnetic Vibrators are great for continuous or intermittent operation. The best and most variable flow of material is made possible by a control that is easy to change. Because there are no moving parts, Syntron Electromagnetic Vibrators are very reliable and require almost no maintenance. Most models come with a fully enclosed design that keeps out dust and water.

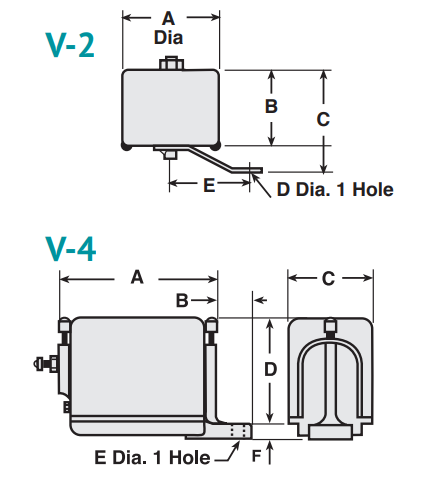

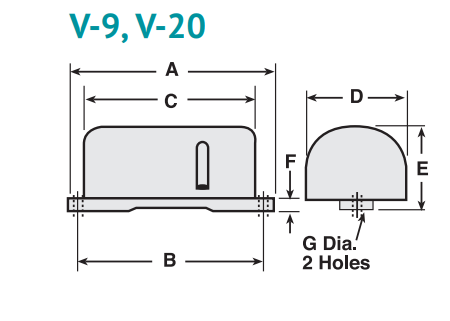

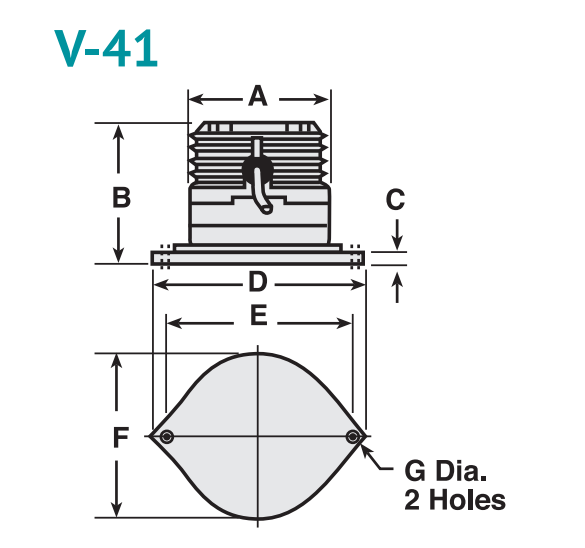

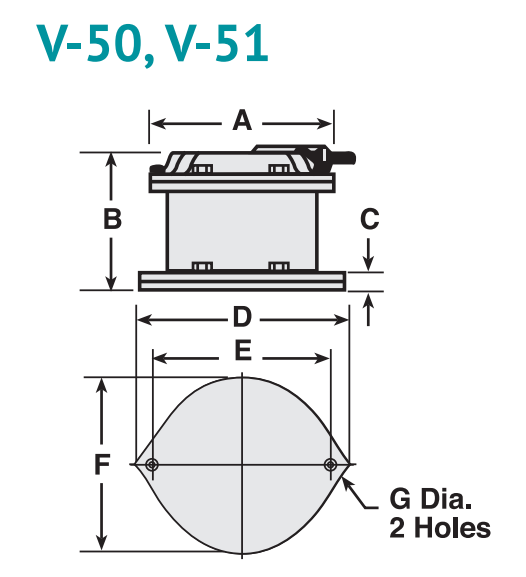

Dph Engineering Syntron V-2 and V-4 Electromagnetic Vibrators are two of the smallest industrial vibrators available. These versatile vibrators can be controlled electrically with a separate control. When these vibrators are operated without control, they can be mechanically controlled by turning an easily accessible adjusting screw. Increased amplitude can be obtained by using rectified AC power. Flexibility and ease of installation are common to both models and the Model V-4 is available with a dust-tight case. Models V-9 and V-20 are compact in size, but at 3600 vpm, they pack enough vibratory “punch” to excel in a wide range of applications. Each is available with a separate dust-tight case. Typical applications for the above models include installations on small bins, handling lightweight materials, or in counting, sorting, or packaging operations. Impact and Cushioned Vibrator Compact Models Models V-50, V-85, and V-180 are “solid” impact vibrators. These units use a metal striking block to produce a positive impact. Models V-41, V-51, V-86, and V-181 are “cushioned” impact vibrators, which utilize a rubber striking block to produce a positive impact. Their high power/low noise characteristics make them ideal for use in confined areas with nearby workers. Physical dimensions and electrical specifications are identical to the “solid” impact type vibrators. Dust-tight and waterproof construction is standard for both versions. Open Models Models V-75 and V-500 feature a power-packed, solid impact, open-type design. They are used on difficult, heavy-duty applications. The V-500 is one of the largest magnetic vibrators available. Both the V-75 and V-500 are available with a separate dust-tight case. Self-Contained Models Models V-9 through V-500 require separate controls unless specifically ordered as self-contained units. Self-contained units include a built-in rectifier and they always operate at full force. Self-contained units are recommended only where no force adjustment is required. Models V-41 and V-500 are not available as self-contained units.

Selecting the Proper Syntron Electromagnetic Vibrator

The primary consideration in vibrator selection is the thickness of the bin or chute wall. Once the proper vibrator model has been selected from the Application Tabulation Table, compare the capacity in the tapered portion of the bin with the rated capacity shown in the table. If the rated capacity is exceeded, multiple vibrators may be required, depending on the material being handled. Stiffeners used to reinforce the bin or chute may also affect the selection or preferred location of the vibrator.

Please contact Dph Engineering Syntron Material Handling for a copy of our data sheet and assistance with the selection of appropriate units for these applications.

Pneumatic Vibrators

DPH Engineering is Authorized Distributors of Syntron Material Handling and offers two types of Syntron® Pneumatic Vibrators—turbine and piston. Turbine models feature rotary action designed to keep noise to a minimum. Operating speed is adjusted by simply varying the air supply. Syntron piston vibrators feature one piece, cast iron, and flat base construction which produces high impact, linear force, and efficient energy transfer. They are ideal for mining, chemical, concrete, plastics, steel, foundry, and paper industries. Syntron Pneumatic Bin Vibrators also come with the technical expertise of Syntron Material Handling’s application specialists, who have been providing product solutions for a wide variety of material handling problems for more than 80 years.

DPH Engineering is Authorized Distributors of Syntron Material Handling and offers two types of Syntron® Pneumatic Vibrators—turbine and piston. Turbine models feature rotary action designed to keep noise to a minimum. Operating speed is adjusted by simply varying the air supply. Syntron piston vibrators feature one piece, cast iron, and flat base construction which produces high impact, linear force, and efficient energy transfer. They are ideal for mining, chemical, concrete, plastics, steel, foundry, and paper industries. Syntron Pneumatic Bin Vibrators also come with the technical expertise of Syntron Material Handling’s application specialists, who have been providing product solutions for a wide variety of material handling problems for more than 80 years.

Dph Engineering Syntron Electric Rotary Vibrators

Dph Engineering Syntron Vibrators offer an efficient, cost-effective means to maintain a free flow of product from bins, hoppers, and chutes, with a direct and positive result on the bottom line. Whether the need is to ensure constant, uninterrupted material flow, or to eliminate the necessity for manual manipulation of a bin, hopper, or bulk material, Syntron Vibrators increase productivity and reduce production costs.

Syntron Electric Rotary Vibrators are motor driven for reduced noise levels. These rugged vibrators are totally enclosed for reliable operation in dusty, dirty, or moist environments. Adjustable eccentric weights allow easy adjustment of force to suit varying applications.

Dph Engineering Syntron Electromagnetic Vibrators

Keep Your Materials Flowing Efficiently and Economically

Dph Engineering Syntron Electromagnetic Vibrators from Syntron Material Handling offer an economical means of maintaining the flow of bulk materials from bins, hoppers, and chutes. They come with an easily adjustable control which provides flexibility and assures optimum flow for the type of material being handled. Furthermore, Syntron Electromagnetic Vibrators can be operated continuously or intermittently depending upon the specific requirements.

To assure the highest standard of quality, Syntron Electromagnetic Vibrators are factory tested and adjusted for optimum performance. Most models come standard with totally enclosed, dust-tight, and waterproof construction. Since these vibrators have no rotating or sliding parts, they are virtually maintenance-free.

Syntron Electromagnetic Vibrators come with the technical expertise of Syntron Material Handling’s application staff, who have been providing product solutions for a wide variety of material handling problems for more than 80 years. Call Syntron Material Handling Application Specialists and request a data sheet or download one from our website at https://dphengg.com/products/syntron/light-industry/bin-vibrators/.

Dph Engineering Syntron Electromagnetic Vibrators may also be ordered online at

https://dphengg.com/products/syntron/light-industry/bin-vibrators/.

Features and Benefits

Electromagnetic design – No rotating or sliding parts; maintenance-free – Ideal for continuous or intermittent operation

- Adjustable control – Varies vibration force with a simple turn of the control knob

- Urethane encapsulated magnet assemblies – Provides protection from moisture and other contaminants – Prevents wire degradation

- Productivity-enhancing performance – No need for manual labor to unclog bins or to keep material flowing

- Simple design, durable, rugged construction – Safe, reliable performance for years of service

- Wide range of sizes – Accommodates your specific application

- Low noise models available – Quiet, reliable operation

Electromagnetic Vibrator Specifications and Dimensions

|

Model |

Speed (vpm 50 Hz) | Speed (vpm 60 Hz) | ||||||||

| Weight | Input Amps |

Without Control |

AC Control |

RC Control |

Without Control |

AC Control |

RC Control |

|||

| lb | kg | 115V | 230V | |||||||

|

V-2 V-4 |

2 1/2 4 1/2 |

1.1 2.0 |

0.3 o.9 |

0.18 0.45 |

6,000 6,000 |

6,000 6,000 |

3,000 3,000 |

7,200 7,200 |

7,200 7,200 |

3,600 3,600 |

|

Model |

A | B | C | D | E | F | ||||||

| in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | |

| V-2

V-4 |

2 7/8

5 5/8 |

73

143 |

2 1/4

1 1/4 |

57

32 |

3 1/16

3 |

78

76 |

13/32

3 3/4 |

10

95 |

2 3/8

17/32 |

60

13 |

—

1/2 |

— 13 |

|

Model |

Weight | Input Amps | Speed | ||||

| lb | kg | 115V | 230V | 460V | (vpm 50 Hz) | (vpm 60 Hz) | |

| V-9

V-20 |

9 1/2

14 |

4.3

6.4 |

1.2

2.0 |

0.75

1.0 |

NA

0.5 |

3,000

3,000 |

3,600

3,600 |

|

Model |

A | B | C | D | E | F | G | |||||||

| in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | |

| V-9

V-20 |

10 1/4

10 1/4 |

260

260 |

9 1/4

9 1/4 |

235

235 |

8

8 |

203

203 |

4 1/4

5 1/8 |

108

130 |

4 1/16

4 5/16 |

103

110 |

9/16

1/2 |

14

13 |

7/16

7/16 |

11

11 |

|

Model |

Weight | Input Amps | Speed | ||||

| lb | kg | 115V | 230V | 460V | (vpm 50 Hz) | (vpm 60 Hz) | |

| V-41 | 25 | 11.3 | 3.5 | 1.75 | 0.88 | 3,000 | 3,600 |

|

Model |

A | B | C | D | E | F | G | |||||||

| in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | |

| V-41 | 6 1/4 | 159 | 6 1/2 | 165 | 7/16 | 11 | 9 3/8 | 238 | 8 1/4 | 210 | 7 3/8 | 187 | 17/32 | 13 |

|

Model |

Weight | Input Amps | Speed | ||||

| lb | kg | 115V | 230V | 460V | (vpm 50 Hz) | (vpm 60 Hz) | |

| V-50, V-51 | 40 | 18.1 | 4.5 | 2.3 | 1.2 | 3,000 | 3,600 |

|

Model |

A | B | C | D | E | F | G | |||||||

| in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | |

| V-50

V-51 |

9 1/2

9 1/2 |

241

241 |

7 1/4

7 1/4 |

184

184 |

15/16

15/16 |

24

24 |

10 3/4

10 3/4 |

273

273 |

9 1/4

9 1/4 |

235

235 |

9 3/4

9 3/4 |

248

248 |

11/16

11/16 |

17

17 |

Related Products: