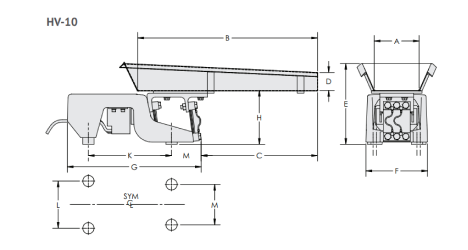

Model HV 10

Model HV 10, Syntron Feeding legacy Suppliers In India

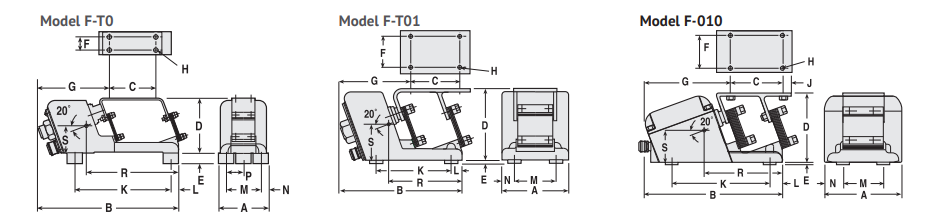

Model F-T0 will handle up to a 31 /2-pound mass with up to .060 stroke.

Model F-010 will handle up to a 13 pound mass with up to .060 stroke.

Model F-T01 will handle up to a 7 pound mass with up to .060 stroke.

Introduction

The Syntron HV-10 feeder is our latest edition to the Syntron feeding legacy. With an IP66 open coil design, the HV-10 renders itself to “clean in place”/wash-down atmospheres with no risk of water ingress. By using Syntron’s 80 years of feeding experience as a platform, our R&D team was able to provide the highest travel speeds and smoothest flow in the market today.

Suitable for a Wide Range of Applications:

- Trough Weight 4-12 lb. • IP-66 • CSA Certified

- 50/60 Hz Design • Stable Footprint • Low Profile Design

- Wide Range of Input Voltage

Great for Use in Food Processing and Packaging:

- Low Product Degradation

- Sanitary Design

- niform Material Flow at Discharge

- Single Tool Air Gap Adjustment

- Open Magnet Design

- Multiple Mounting Configurations

- Super Resonant Tuning

- Linear Speed Control

- Wash Down Capable

Model HV-10 Features

Suitable for a Wide Range of Applications:

• Trough Weight 4-12 lb.

• IP-66

• CSA Certified

• 50/60 Hz Design

• Low Profile Design

• Stable Footprint

Great for Use in Food Processing and Packaging:

• Low Product Degradation

• Sanitary Design

• Wash Down Capable

• Uniform Material Flow at Discharge

• Single Tool Air Gap Adjustment

• Multiple Mounting Configurations

• Super Resonant Tuning

• Linear Speed Control

• Open Magnet Design

| Trough Type | A | B | C | D | E * | F | G | H * | K | L | M | |

|

Std. Flat Pan |

(in) | 6 | 24 | 12 15/16 | 2 | 9 | 6 7/8 | 14 13/16 | 6 | 9 1/4 | 5 1/4 | 4 1/2 |

| (mm) | 152 | 610 | 329 | 51 | 229 | 175 | 376 | 152 | 235 | 133 | 114 | |

|

Spec. Flat Pan |

(in) | 5 | 20 | 10 15/16 | 2 | 9 | 6 7/8 | 14 13/16 | 6 | 9 1/4 | 5 1/4 | 4 1/2 |

| (mm) | 127 | 508 | 278 | 51 | 229 | 175 | 376 | 152 | 235 | 133 | 114 | |

|

Spec. Flat Pan |

(in) | 8 | 20 | 10 15/16 | 2 | 10 | 6 7/8 | 14 13/16 | 7 | 9 1/4 | 5 1/4 | 4 1/2 |

| (mm) | 203 | 508 | 278 | 51 | 254 | 175 | 376 | 178 | 235 | 133 | 114 | |

|

Spec. Flat Pan |

(in) | 10 | 20 | 10 15/16 | 2 | 10 | 6 7/8 | 14 13/16 | 7 | 9 1/4 | 5 1/4 | 4 1/2 |

| (mm) | 254 | 508 | 278 | 51 | 254 | 175 | 376 | 178 | 235 | 133 | 114 | |

|

Spec. Flat Pan |

(in) | 12 | 14 | 6 11/16 | 2 | 10 | 6 7/8 | 14 13/16 | 7 | 9 1/4 | 5 1/4 | 4 1/2 |

| (mm) | 305 | 356 | 170 | 51 | 254 | 175 | 376 | 178 | 235 | 133 | 114 | |

Syntron® vibra drive units

Syntron Vibra drive units are isolated from the surrounding building and are supported by rubber mountings for most models. Three types of rubber mountings are available. The BF-4 drive features sandwich mounts. The F-T02, BF-4 LF, and Velocity RS drive feature coil springs.

Vibra Drive Units by DPH Engineering provide directional vibratory conveying movement to a track, trough, or any responsive surface. They are designed for use with packaging machines or special process equipment requiring a metered flow of bulk materials or parts. Vibra drive units are small, compact, electromagnetic drives encased in dust-tight housings. The mounting bracket has pre-drilled holes for easy attachment to the mass to be vibrated. Drive type and the number of drives are determined by the width, length, and weight of the mass to be vibrated. Below the deck, base mounting is standard for all units. Controls are available to operate a single-drive unit or multiple drive configurations. DPH Engineering’s Vibra Drive Units operate from either 115 or 230-volt, single-phase, 50 or 60-cycle power. Models BF-2, BF-3, BF-4, and BF-4 LF Vibra drive units also operate from 460 volts; all other units require a step-down transformer when the operating voltage is 460 volts. Our Vibra Drives are designed for easy adjustment, including external tuning on most models.

For many international companies that are leaders and innovators in their fields, DPH Engineering is an authorized distributor for the Indian market. One such company is Syntron whose products we supply and our most recent addition to the history of Syntron feeding is the Syntron HV-10 feeder. Our R&D team was able to offer the fastest travel speeds and smoothest flow currently available on the market by employing Syntron’s 80 years of feeding knowledge as a basis.

Custom designed sandwiching processes rely on Syntron drives to ensure

consistent, controlled delivery and smooth, gentle cookie, wafer or cracker handling.

| Model | A | B | C | D | E ● | F | G | H | J | K | L | M ▲ | N | P | R ■ | S ■ | T | |

| F-T0 | (in) | 31/4 | 8 3/4 | 3 | 3 9/16 | 11/16 | 1 | 4 1/4 | 7/32 dia | – | 6 1/4 | 1/2 | 2 1/4 | 1/2 | 1 1/8 | 5 1/2 | 1 7/16 | – |

| (mm) | 82.6 | 222.3 | 76.2 | 90.5 | 17.5 | 25.4 | 107.9 | 5.6 | – | 158.8 | 12.7 | 57.2 | 12.7 | 28.6 | 139.7 | 36.5 | – | |

| F-T01 | (in) | 5 | 9 1/8 | 3 3/4 | 5 3/8 | 1/4 | 1 3/4 | 5 1/4 | 11/32 dia | – | 5 5/8 | 13/16 | 3 1/8 | 15/16 | – | 5 1/2 | 2 1/2 | – |

| (mm) | 127 | 231.8 | 95.3 | 136.5 | 6.4 | 44.5 | 133.4 | 8.7 | – | 142.9 | 20.6 | 79.4 | 23.8 | – | 139.7 | 63.5 | – | |

| F-T0-2 | (in) | 5 | 10 7/8 | 3 3/4 | 5 3/8 | 11/16 | 13/4 | 6 21/32 | 11/32 dia | – | 5 5/8 | 13/16 | 3 1/8 | 15/16 | – | 5 11/16 | 2 1/2 | – |

| (mm) | 127 | 276.2 | 95.3 | 136.5 | 27 | 44.5 | 169.1 | 8.7 | – | 142.9 | 20.6 | 79.4 | 23.8 | – | 144.5 | 63.5 | – | |

| F-010 | (in) | 6 | 10 7/8 | 3 3/4 | 5 9/16 | 3/16 | 1 3/4 | 7 1/8 | 11/32 dia | 3/4 | 7 3/4 | 1 | 3 1/8 | 1 7/16 | – | 6 3/8 | 2 5/16 | – |

| (mm) | 152.4 | 276.2 | 95.3 | 141.3 | 4.76 | 44.5 | 181 | 8.7 | 19 | 197 | 25.4 | 79.4 | 36.5 | – | 161.9 | 58.7 | – | |

Specifications

| F-T0 | F-T01 | F-T02 | F-010 | |

| Approx. Power Consumption★ Approx. Current Input★ Approx. Net Weight, Drive |

15 Watts .35 amps 9 1/2 lb |

20 Watts .9 amps 21 lb |

30 Watts 1.5 amps 33 lb |

50 Watts 2.0 amps 33 1/2 lb |