Volumetric Feeder Machines

Volumetric Feeder Machines Suppliers in India

Syntron® volumetric feeder machines

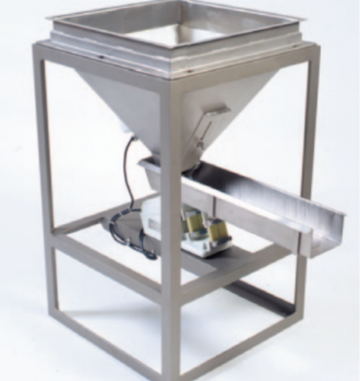

Syntron Volumetric Feeder Machine

with conical supply hopper.

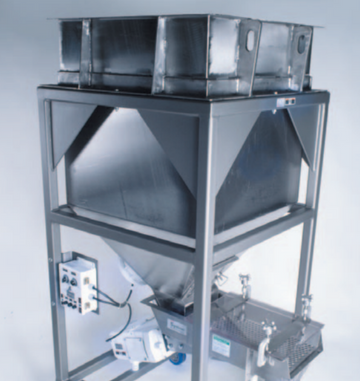

Volumetric Feeder with customized rectangular hopper.

Syntron Volumetric Screening

Feeder Machine.

Total control in material handling for feeding, blending or packaging

Simple design and flexible control account for the efficient, economical performance of Syntron volumetric feeder machines, and the growing industrial preference for them. These units can feed most dry bulk materials and can be supplied to conform to FDA and USDA specifications. There are six different models of Syntron volumetric feeder machines.

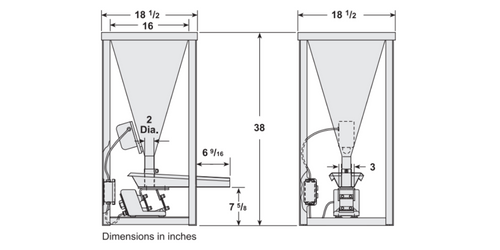

Syntron volumetric feeder machine designs include four basic components: a supply hopper, a hopper vibrator, a vibrating feeder, and the supporting frame. Supply hoppers are usually fabricated from mild steel but are available in stainless steel. Most supply hoppers are conical; however, rectangular hoppers are an option. Adjusting the gate height between the hopper and feeder trough regulates material depth for most models. The material depth for model FM-T0 is regulated by hopper tilt.

Arching, plugging, or bridging of materials in the hopper is prevented through the incorporation of an electromagnetic vibrator. The hopper vibrator features a variable power control, assuring the free flow of material to the feeder trough. DPH Engineering supplies volumetric feeder machines whose vibrating feeders operate at 3,600 vpm (at 60 Hz) and trough options include flat pan (standard), V-shaped, tubular, or screening troughs of mild or stainless steel.

Because of their simple design, volumetric feeder machines are dependable and have an exceptionally long service life. There are no moving parts such as motors, belts, gears, valves, connecting arms, or sliding rods in such feeders to wear or lubricate.

Drives on vibrating feeders are available with dust-proof, dust-tight, and waterproof construction. For dust-tight sealing, special covered or tubular troughs feature flexible seals on the discharge end of the supply hopper. In addition, flexible seals that seal the top of the supply hopper to an overhead chute, as well as removable dust covers for the supply hopper are also available. These units are virtually noiseless and meet the applicable OSHA specifications. Even at maximum feed, the hum is the only indication that the machine is operating.

Volumetric feeder machines by DPH Engineering are supplied with electric controls that can be mounted separately at any desired location. Standard controls contain operating switches, rectifiers, and rheostats. The electric control regulates the feed rate by varying the vibrating intensity of the electromagnetic feeder. A graduated dial on the control panel permits variation in the flow speeds. Timers are also available in such feeder machines to provide intermittent feed.

Capacities of volumetric feeder machines vary with different materials. These materials have a lot to do with the extent of capacities that the feeder machines have. Lighter and finer materials result in less capacity and heavier materials result in higher capacities.

Volumetric Feeder Machine Models and Dimensions

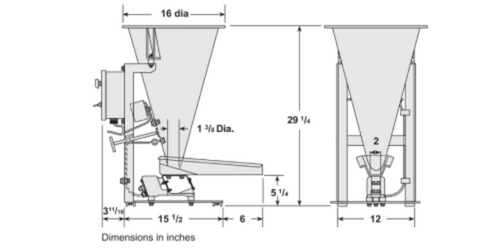

Model FM-T0-3/4

Syntron® Model FM-T0-3/4 is one of the smallest, most economical volumetric feeder machines available. This dependable unit is usually preferred for light-capacity, continuoususe operation. This model features a 3/4 cubic foot supply hopper, a V-2 hopper vibrator, an F-TO vibrating feeder with 2 x 16-inch flat pan trough and a solid-state control. Configured for 115 volt, single-phase 50 or 60 cycle power. Operating at 230 or 460 volts requires a step-down transformer. Optional equipment includes a stainless steel supply hopper and/or feeder trough, trough and hopper covers.

WITH STANDARD 2-INCH X 16-INCH FLAT PAN TROUGH

MAXIMUM MATERIAL CAPACITY (sand @ 100 lb C/F) .625 TPH

SPECIFICATIONS

Power Consumption* 30 Watts Net Weight, machine 55 lb

Current Input* 1.20 amps Net Weight, Control 9 lb

*115 volt, 60 cycle Shipping Weight, Both 125 lb

Control (inches) – 6 15/16 W x 9 1/2 H x 3 5/8 D

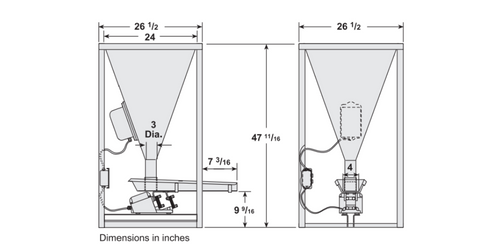

Model FM-010-3

Syntron® Model FM-010-3, while similar in design to the FM-T01-1, has a larger capacity. This machine is furnished with a 3 cubic foot supply hopper, a V-20 hopper vibrator and a separate solid-state control. Model FM-010-3 includes an F-010 vibrating feeder with 4 x 24-inch flat pan trough. The FM-010-3 operates on 115, 230 or 460 volt, single-phase, 50 or 60 cycle power. A 460-volt power configuration requires a step-down transformer. Optional equipment includes stainless steel supply hoppers and feeder troughs and plastic, mild steel or stainless steel covers for trough and hopper. Hoppers are available in conical or rectangular design.

WITH STANDARD 4-INCH X 24-INCH FLAT PAN TROUGH

Maximum Material Capacity

(sand @ 100 lb C/F) 4 TPH

SPECIFICATIONS

Power Consumption*125 Watts Net Weight, machine 180 lb

Current Input* 4.0 amps Net Weight, Control 9 lb

*115 volt, 60 cycle Shipping Weight, Both 340 lb

Control (inches) – 6 15/16 W x 9 1/2 H x 3 5/8 D

Model FM-T01-1

Syntron Model FM-T01-1, with a separate solid state control as standard equipment, has wider application than any other medium-capacity volumetric feeder machine in the

Syntron line. This unit features a 1 cubic foot supply hopper, V-4 hopper vibrator and F-TO1 vibrating feeder with a 3 x 18-inch flat pan trough. Configured for 115 or 230 volt, singlephase, 50 or 60 cycle power. Operating at 460 volt requires a step-down transformer. Optional equipment includes a stainless steel supply hopper and/or feeder trough, and stainless steel covers for trough and hopper.

WITH STANDARD 3-INCH X 18-INCH FLAT PAN TROUGH

MAXIMUM MATERIAL CAPACITY

(sand @ 100 lb C/F) 2 TPH

SPECIFICATIONS

Power Consumption* 75 Watts Net Weight, machine 100 lb

Current Input* 1.75 amps Net Weight, Control 9 lb

*115 volt, 60 cycle Shipping Weight, Both 160 lb

Control (inches) – 6 15/16 W x 9 1/2 H x 3 5/8 D

Volumetric Feeder Machine Models and Dimensions, cont’d.

Model FM-212-3

Syntron® FM-212-3 offers economical, high-capacity performance. Standard construction includes a 3 cubic foot supply hopper, a V-20 hopper vibrator, a separate solid-state control and a powerful F-212 vibrating feeder with a 10 x 24-inch flat pan trough. Configured for 115, 230 or 460 volt, single-phase, 50 or 60 cycle power. Optional equipment includes stainless steel supply hoppers and/or feeder troughs and special 6, 10 or 18 cubic foot supply hoppers, with conical or rectangular design.

WITH STANDARD 10-INCH X 24-INCH FLAT PAN TROUGH

Maximum Material Capacity

(sand @ 100 lb C/F) 20 TPH

SPECIFICATIONS

Power Consumption*200 Watts Net Weight, machine 475 lb

Current Input* 6.5 amps Net Weight, Control 9 lb

*115 volt, 60 cycle Shipping Weight, Both 600 lb

Control (inches) – 6 15/16 W x 9 1/2 H x 3 5/8 D

DPH Engineering has made a name for itself as a leading Volumetric Feeder Machines Suppliers in India. At DPH Engineering, we are aware of how important it is to your bottom line to have high-quality, dependable machinery that is performing at its best. We are dedicated to providing value to our clients before, during, and after the sale because of this. Your satisfaction is our first focus at DPH Engineering.

Visit our website or contact us today for more details and information!