There are several different types of material handling equipment that can help factories transfer items from one place to another. There are many different kinds of conveying systems that can be used to move solid, semi-solid, or liquid products. The goal of this blog is to tell you about the vibrating conveyor and help you decide if it is the best conveyor for your requirements.

To begin with, What are vibrating conveyors?

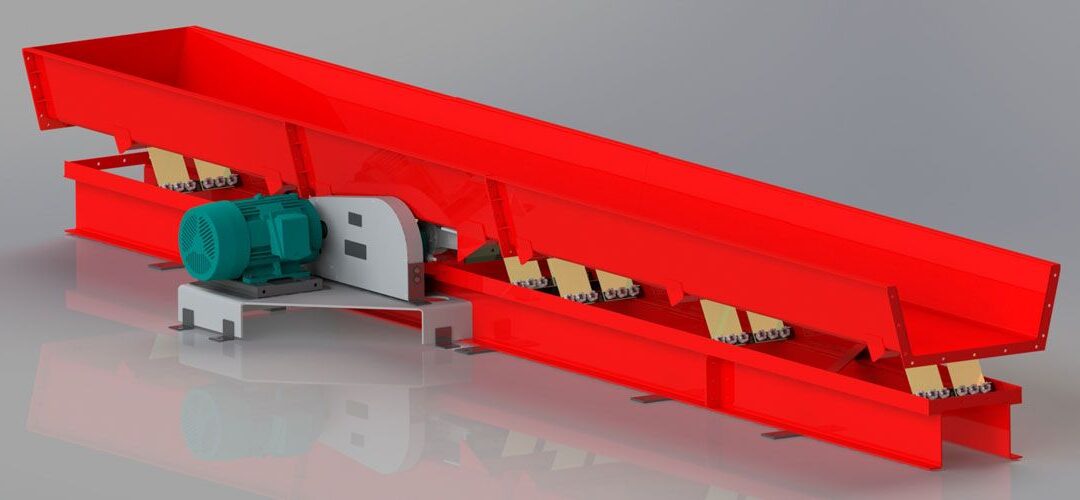

A vibrating conveyor vibrates. This is a completely random statement, but it shows the main purpose of this type of conveyor, which is to use vibrational energy to put static and dynamic stresses on aggregate materials and move them up or down a track. Usually, the surface that moves the material is a flat trough with vibrating parts that shake the trough in a longitudinal direction. Coal, limestone, food ingredients, sand, gravel, and other bulk products might “jump” toward one end of the trough in this way. This hopping action can move thick beds of bulk, like the wood chips. When it happens many times per second, the bed of materials moves. When moving things on a flat surface or a shallow slope, a vibrating belt conveyor is often the best option because it can move a wide range of bulk materials.

How do vibrating conveyors work?

It will be hard to say how all vibrating conveyors work in general because their function depends so much on the motor and the way the device is built. Most vibrating conveyors have a motor system that sends a force that oscillates at a set frequency and amplitude to the trough. Most vibrating conveyors try to reduce amplitude while increasing frequency. Amplitude is the distance a material moves in the trough during one full movement of the trough, which is also called the trough stroke. Since the frequency and amplitude of these vibrating conveyors can be changed precisely, they are often called “controlled” conveyors. Natural-frequency vibrating conveyors use springs and other parts to make the trough vibrate at its natural frequencies. These conveyors use less energy and spread vibrations evenly across the trough. Most vibrating conveyors use natural frequency approaches. Regulated conveyors, on the other hand, tend to be more specialized. Since different materials (and even different batches of the same material) have varying reactions to the specified amplitude and frequency of the conveyor, a lot of math goes into designing a good one.

Vibrating conveyors can be driven in three basic ways: by cranks and springs, by rotating weights, or by electromagnets. Rotating weights and electromagnets both do the same thing, but they do it in different ways. Rotating weights use rotating eccentric weights, while electromagnets use rotating magnetic fields. Since all driving systems have been shown to work, the advantages of one over another are very different and depend heavily on the application and the working environment.

Where are vibrating conveyors used?

Vibrating conveyors are used in places where cleanliness and low maintenance are very important, like in the food and chemical, rubber, foundry, processing, and other industries. They function normally in places where there is a lot of dirt, heat, and corrosive ingredients. As a bonus, they can clean themselves, so you never have to worry about grime or dirt getting in the way of transporting anything useful, like a bag of potato chips. They pose little threat when left to fend for themselves and are easy to make. The only practical limits on how vibrating conveyors can be used are their height and width limits.

Let’s discuss the types of vibrating conveyors

It’s hard to classify the types of conveyors because there aren’t many different subclassifications. Instead, they are usually grouped together based on how they will be used or what type of duty they will perform. Vibratory conveyor manufacturers don’t help matters by assigning specific functions and forms to each kind of vibrating conveyor they produce. The purpose of this blog is to provide examples of the most common kinds of vibrating conveyors so the reader can see what kinds of vibrating conveyors are out there and make an informed decision about whether or not to acquire one.

- Standard duty vibrating conveyors

Standard-duty vibrating conveyors work best with materials with a medium to low density, like plastics, wood, and porous gravel. Depending on the application, they can be stationary or mobile, and their capacities can range from 1 to 40 tons per hour at speeds up to 60 feet per minute. Because of their durability and low maintenance requirements, these conveyors are a good choice for transporting aggregates. They have many different uses, including in the food and chemical industries, in industry, and with polymers.

- Heavy-duty vibrating conveyors

Heavy-duty vibrating conveyors are used to move big, heavy things like rocks and metal, and they can handle a lot of speed and acceleration. They are often used to put in dampers, dashpots, stands, and other things that need a certain kind of base support. Their capacities surpass 500 tons per hour at speeds up to 90 feet per minute. When compared to lighter-duty vibrating conveyors, the power needs of a heavy-duty conveyor’s motor are much higher. They are used in industries like foundries, large manufacturing, lumber, rubber, and others that are similar.

- Vibratory feeders

The vibratory feeder is a special type of vibrating conveyor. It works the same way as other vibrating conveyors, but its purpose is to feed materials evenly into another machine. When other types of feeders can’t be used but precise volume rates are needed for continuous weighing, these work great. In addition to the shape shown in Figure 5, vibratory feeders can also be used in the shape of a bowl to reliably move small, oddly shaped parts like screws, rings, and other things. They serve a variety of purposes in the petrochemical, food, hardware, and industrial sectors.

- Oscillating Conveyors

Even though the term “oscillating conveyor” is not used by every manufacturer, it does come up from time to time. Some people think of oscillating conveyors as a subset of vibrating conveyors because they move with a low frequency and a high amplitude compared to standard vibrating conveyors. Therefore, industries like the lumber industry, trash management, and recycling make use of oscillating conveyors to move large quantities of goods. These conveyors could be used to move wood scraps from an upstream system to a discharge location. A vibrating conveyor moves things more gently than an oscillating conveyor because it has lower amplitudes and higher frequencies. In the quarrying industry, oscillating conveyors are known as jump conveyors, and in the hard rock mining industry, they are known as grasshopper conveyors.

What are the criteria for selection and the required specifications?

As we just talked about, the term “vibrating material handling equipment” refers to a wide range of machines and tasks. This makes it difficult to pick one for use, as there are often several possibilities and variants to choose from. If you’re looking for a great troughed belt conveyor, you should definitely be aware of the selection criteria.

To figure out the right load capacity and pieces per minute, you need to know exactly what will be moved by the conveyor, how much of it needs to be moved, and how fast. Your provider can use these numbers to figure out the right size, shape, and load rating for the conveyor. Your supplier should be able to tell you what the best speed and capacity are for your project. This way, you can never go wrong in the vibrating conveyor calculation.

- Load capacity & pieces per minute

Find out the distance the aggregate has to go, the ideal width, and the required amount of vibration to shift the material. For example, if stones were being moved over a long distance, the trough and drive of a boulder conveyor would need to be bigger and wider. With these things in mind, you’ll be able to choose the best vibrating conveyor for your job and plan for how much drive and power it will need.

- Trough length and vibrational frequency

Most of the time, these types of conveyors are low-maintenance and don’t need to be controlled. However, control can be added if the conveyors need to be part of a larger control system. If command is unnecessary, numerous low-intervention strategies exist. Find out whether there are any unique needs, like containment, sterile materials, or dampening in the foundation. You should tell your supplier about these things and any others that you think are important so that they can help you find the best options.

Contact DPH Engineering right away!

DPH Engineering ranks highly among the best suppliers of industrial equipment in India. We’ve been giving our customers state-of-the-art manufacturing equipment and good service even after the sale is done. We can give you both expert advice and the real-world answers you need about manufacturing. Conveyor belts may greatly improve the efficiency of an assembly line, so if this is something you’re seriously considering, don’t hesitate to get in touch with us.

Are you thinking of using conveyor belts in your production line? DPH Engineering is a well-known company that sells packaging equipment and related accessories, like conveyor belts. They have earned these accolades by being experts at designing, building, manufacturing, repairing, installing, and starting up this equipment. DPH Engineering has specialized in material handling equipment needs since its establishment.